BSD-ON:10.1

The Control (Center) Thermistor has an open circuit.

Initial Actions

•

Power OFF/ON

Procedure

Check the installation of the Fuser Unit. The Fuser Unit is securely installed.

Y

N

Install the Fuser Unit securely.

Check the resistance of the Center Thermistor between P600-5 and P600-6 (BSD 10.1

2/Flag

3). The resistance is 3k ohms or higher.

Y

N

Replace the Fuser Unit

(PL

5.1).

Check the wire between

P/J410

and

J600

2/Flag

3). The wire between J410 and

short circuit.

Y

N

Repair the open circuit or short circuit.

Replace the Fuser Unit

(PL

5.1). If the problem persists, replace the MCU PWB

Launch Version

WorkCentre 5225, 5230

for an open circuit or a short circuit (BSD 10.1

J600

is conducting without an open circuit or a

(PL

Flag

Flag

9.1).

February, 2008

2-91

Status Indicator Raps

010-313

- Page 1

Service Manual WorkCentre 5222 5225 / 5230 Tabloid Black-and-white Multifunction Printer… -

Page 2: Launch Version

Xerox does not warrant or represent that it will notify or provide to such customer a commercial environment. Operation of this equipment in a residential area is likely to any future change to this documentation.

- Page 3

Introduction About this Manual ………………….Organization……………………How to Use this Documentation………………Symbology and Nomenclature ………………Translated Warnings ………………….. viii Launch Version Introduction February, 2008 WorkCentre 5225, 5230… - Page 4

About this Manual Organization This Service Manual is part of the multinational documentation system for WorkCentre 5225 / This Service Manual is divided into eight sections. The titles of the sections and a description 5230. The Service Documentation is used in order to diagnose machine malfunctions, adjust of the information contained in each section are contained in the following paragraphs: components and has information which is used to maintain the product in superior operating Section 1: Service Call Procedures… - Page 5

Section 7: Wiring Data How to Use this Documentation This section contains drawings, lists of plug/jack locations, and diagrams of the power distribu- The Service Call Procedures in Section 1 describe the sequence of activities used during the tion wire networks in the machine. This section also contains the Block Schematic Diagrams. service call. - Page 6

Symbology and Nomenclature CAUTION The use of controls or adjustments other than those specified in the Laser Safety Training Pro- The following reference symbols are used throughout the documentation. gram may result in an exposure to dangerous laser radiation. For additional information, review the Laser Safety Training program. Warnings, Cautions, and Notes Warnings, Cautions, and Notes will be found throughout the Service Documentation. - Page 7

Electrostatic Discharge (ESD) Field Service Kit The ESD Field Service Kit should be used whenever Printed Wiring Boards or ESD sensitive components are being handled. This includes activities like replacing or reseating of circuit The purpose of the ESD Protection Program is to preserve the inherent reliability and quality of boards or connectors. - Page 8

Signal Nomenclature DC Voltage Measurements in RAPs Refer to Figure 7 for an example of Signal Nomenclature used in Circuit Diagrams and BSDs. The RAPs have been designed so that when it is required to use the DMM to measure a DC voltage, the first test point listed is the location for the red (+) meter lead and the second test point is the location for the black meter lead. - Page 9

Translated Warnings Introduction Launch Version February, 2008 viii WorkCentre 5225, 5230… - Page 10

Quand ces symboles s’affichent le représentant Xerox est prévenu des risques REP 2.6.2 Left Hand (L/H) Upper Cover Unit encourus concernant une exposition au rayon laser. - Page 11

REP 4.1.1 Xero/Developer Cartridge WARNING To avoid personal injury or shock, do not perform repair or adjustment with electrical WARNING power applied to the machine. To avoid personal injury or shock, do not perform repair or adjustment with electrical DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte- power applied to the machine. - Page 12

To avoid personal injury or shock, do not perform repair or adjustment with electrical REP 11.6.2 Lamp Wire Harness power applied to the machine. WARNING DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte- nance ou reglage avec le cordon d’alimentation branche. To avoid personal injury or shock, do not perform repair or adjustment with electrical REP 11.3.1 Platen Glass… - Page 13

WARNING DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte- nance ou reglage avec le cordon d’alimentation branche. To avoid personal injury or shock, do not perform repair or adjustment with electrical REP 15.1.2 DADF Platen Cushion power applied to the machine. - Page 14

WARNING DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte- nance ou reglage avec le cordon d’alimentation branche. To avoid personal injury or shock, do not perform repair or adjustment with electrical REP 16.3.1 Booklet PWB power applied to the machine. - Page 15

WARNING DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte- nance ou reglage avec le cordon d’alimentation branche. To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine. DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte- nance ou reglage avec le cordon d’alimentation branche. - Page 16

1 Service Call Procedures Service Call Procedures………………..Initial Actions ……………………Call Flow ……………………. Detailed Maintenance Activities (HFSI)…………….Cleaning Procedures………………….. Final Actions……………………Launch Version Service Call Procedures February, 2008 WorkCentre 5225, 5230… - Page 17

Service Call Procedures Launch Version February, 2008 WorkCentre 5225, 5230… - Page 18

Service Manual. Perform each step in order. Inspect any rejected copies. Inquire as to, or otherwise determine, the paper quality and weight, the specified paper for optimum Image Quality, 24# Xerox Color Expres- Initial Actions sions (NASG) or ColorTech+90gsm (ESG). - Page 19

• Original Type — Photo and Text Halftone Call Flow • R/E — Auto This procedure should be performed at every service call. • Lighter/Darker — Auto Contrast • Sharpness — Normal Initial Actions • Preset Color Balance — Normal Ask the operator about the problem. - Page 20

There is a problem with Receive transmission test. Perform Receive trans- Table 1 Other Faults mission tests with other stations within the company. Check that there is Problem Corrective Action no problem with the machine and then ask the customer to check the sta- ADF inoperative after PWB Reload Software 9.3.1. - Page 21

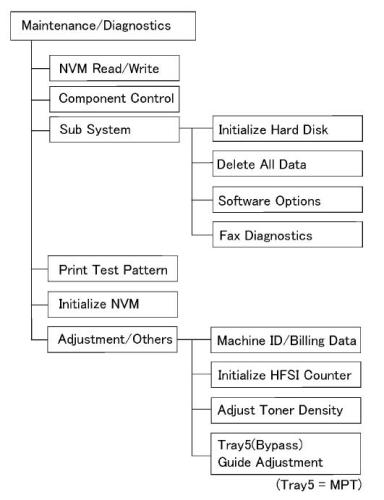

Detailed Maintenance Activities (HFSI) Table 1 High Frequency Service Items Thres- Procedure Counter Name hold Service Action to be performed Access Diagnostic Routines. 955-808 Duplex Feed Counter 912K Replace the Document Nudger Roll, Feed Enter UI Diagnostics (Entering UI Diagnostics in UI Diagnostic Mode). - Page 22

Cleaning Procedures Final Actions Purpose Purpose To provide cleaning procedures to be performed at every service call. To provide a guide for procedures to be done at the end of every service call. Procedure Procedure CAUTION Ensure that the exterior of the copier/printer and the adjacent area are clean. Use a dry cloth or a cloth moistened with water to clean the copier/printer. - Page 23

Service Call Procedures Launch Version February, 2008 Cleaning Procedures, Final Actions WorkCentre 5225, 5230… -

Page 24: Table Of Contents

2 Status Indicator RAPs 002 HDD 003-931 400 DPI Scan RAP……………….. 2-38 003-932 600 DPI Scan RAP……………….. 2-38 002-500 UI Error RAP ………………… 2-15 003-933 300 DPI Scan RAP……………….. 2-39 002-770 Job Template Processing — HD Full RAP …………2-15 003-934 400 DPI Scan RAP………………..

-

Page 25: Table Of Contents

005-197 Prohibit Combine Size JAM RAP …………..2-70 012-280 (A-Finisher) Eject Home Sensor OFF Fail …………2-110 005-198 Too Short Size JAM RAP……………… 2-71 012-283 (A-Finisher) Set Clamp Home Sensor ON Fail ……….2-111 005-199 Too Long Size JAM RAP ……………… 2-72 012-284 (A-Finisher) Set Clamp Home Sensor OFF Fail……….

-

Page 26: Table Of Contents

013 SB-Booklet 016-348 ESS PageMemory Failure-2 RAP …………..2-178 016-350 ESS SEEP-ROM Failure-1 RAP …………… 2-178 013-210 Booklet Staple Move Home SNR ON Fail RAP ……….2-153 016-351 ESS SEEP-ROM Failure-2 RAP …………… 2-179 013-211 Booklet Staple Move Home SNR OFF Fail RAP ……….2-153 016-360 ESS UI Failure-1 RAP………………

-

Page 27: Table Of Contents

016-583 Lock Folder Creation Failure RAP …………..2-204 016-738 PS Booklet Output Size Illegal RAP…………..2-230 016-584 Folder Creation Failure RAP …………….2-204 016-739 Document and Output Mismatch RAP ………….. 2-230 016-585 File Delete Failure RAP ………………2-205 016-740 Output Tray Incorrect RAP…………….2-231 016-586 Lock Folder Delete Failure RAP ……………

-

Page 28: Table Of Contents

016-792 Specified Job RAP ……………….. 2-257 018-706 LDAP RAP ………………….2-282 016-793 MF I/O HD Full RAP………………2-258 018-707 LDAP RAP ………………….2-283 016-799 PLW Print Instruction RAP…………….2-258 018-708 LDAP RAP ………………….2-283 016-981 HDD access error RAP ………………2-259 018-710 LDAP RAP ………………….

-

Page 29: Table Of Contents

021 FAX 024-910 Tray 1 size mismatch RAP…………….2-338 024-911 Tray 2 size mismatch RAP…………….2-339 021-947 Subtractive Accessory Disable (Scan) RAP …………. 2-309 024-912 Tray 3 size mismatch RAP…………….2-340 021-948 Subtractive Accessory Disable (Print) RAP …………2-309 024-913 Tray 4 size mismatch RAP…………….2-341 021-949 Subtractive Accessory Disable RAP …………..

-

Page 30: Table Of Contents

024-917 Stacker Tray Staple Set Over Count RAP …………2-370 027-549 SMB Protocol error 4-009 RAP …………….. 2-397 024-928 Scratch Sheet Compile RAP …………….2-370 027-564 SMB Protocol error 4-024 RAP …………….. 2-397 024-976 Finisher Staple Status Failed RAP…………..2-371 027-565 SMB Protocol error 4-025 RAP ……………..

-

Page 31: Table Of Contents

027-773 SMTP Server Communication Timeout RAP ………… 2-423 034-505 Fax Communication RAP……………… 2-449 027-774 Address Inaccurate Character RAP …………..2-423 034-506 Fax Communication RAP……………… 2-449 027-775 Too Many SMTP Address RAP ……………. 2-424 034-507 Fax Communication RAP……………… 2-450 027-776 SMTP Server Error (EHLO) RAP …………..2-424 034-508 Fax Communication RAP………………

-

Page 32: Table Of Contents

035-715 Fax Protocol RAP ………………… 2-475 042 Drives 035-716 Fax Protocol RAP ………………… 2-475 042-323 Drum K Motor Drive Failure RAP …………..2-501 035-717 Fax Protocol RAP ………………… 2-476 042-325 Main Motor Failure RAP………………2-501 035-718 Fax Protocol RAP ………………… 2-476 047 Communication 035-719 Fax Protocol RAP …………………

-

Page 33: Table Of Contents

073-210 Tray 3 Lift Up Failure RAP …………….2-532 081-799 Registered Destination RAP …………….2-565 073-211 Tray 3 Broken RAP ………………. 2-533 091 Drum 071-940 Tray 3 Lift Up RAP ……………….. 2-533 091-402 Drum Life Over RAP ………………2-567 074 Tray 4 091-441 Drum Life Near End of Life RAP ……………

-

Page 34: Table Of Contents

116-322 WebDAV S/W Fail RAP ………………2-592 116-382 ABL Initialize RAP ………………… 2-618 116-323 ESS NVRAM R/W Check RAP …………….. 2-592 116-385 IDC Software RAP ……………….. 2-618 116-324 System Controller RAP ………………2-593 116-388 MCC RAP………………….2-619 116-325 ESS Fan RAP ………………..2-593 116-389 RAM Install RAP ………………..

-

Page 35: Table Of Contents

123-325 Object Creation RAP………………2-643 124-315 Serial Number Mismatch RAP …………….2-669 123-326 Memory Overflow RAP ………………2-644 124-316 Product Mode RAP ………………. 2-670 123-327 Button Overflow RAP ………………2-644 124-317 All Product Mode RAP ………………2-670 123-328 UI Internal Range RAP ………………2-645 124-318 Product Type Software Key RAP …………..

-

Page 36: Table Of Contents

127 Software 127-310 ESR Task RAP ………………..2-697 127-314 WSD Print S/W Fail RAP ……………… 2-697 127-353 LPD Software RAP ………………. 2-698 127-396 Mail I/O Software RAP ………………2-698 127-398 IPP Software RAP………………… 2-699 127-399 JME Software RAP ………………. 2-699 133 Fax Control 133-210 Fax Parameter RAP ………………

-

Page 37: Workcentre

Status Indicator Raps Launch Version February, 2008 2-14 WorkCentre 5225, 5230…

- Page 38

002-500 UI Error RAP 002-770 Job Template Processing — HD Full RAP UI detection error while in CUI scan job start: Job aborted due to insufficient HDD capacity during Job Template processing. Procedure IIT is occupied. Fault is occurring. Ask customer to separate job into smaller parts. Helpful information may be found in User Service is not CUI. - Page 39

Status Indicator Raps Launch Version February, 2008 002-500, 002-770 2-16 WorkCentre 5225, 5230… - Page 40

003-318 IIT Soft Failure RAP 003-319 IIT Video Driver Detection Failure RAP The IIT software is faulty. A Compression Threshold overflow, DMA Transfer error, or Other compression system errors were detected. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). - Page 41

003-320 IISS-ESS Communication Failure 1 RAP 003-321 IISS-ESS Communication Failure 2 RAP An abnormal parameter is set for the send function. The acknowledgement could not be received after 2 resend attempts. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). - Page 42

003-322 IISS-ESS Communication Failure 3 RAP 003-323 IISS-ESS Communication Failure 4 RAP The Packet number of the sent Message Packet is incorrect. The Message Length of the sent Message Packet is incorrect. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). - Page 43

003-324 IISS-ESS Communication Failure 5 RAP 003-325 IISS-ESS Communication Failure 6 RAP Message Length of the Packet is incorrect. A parity error was detected by hardware in the IIT/IPS PWB. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). Check the P/Js on the IIT/IPS PWB 11.3). - Page 44

003-326 IISS-ESS Communication Failure 7 RAP 003-327 IISS-ESS Communication Failure 8 RAP Framing error was detected by hardware in the IIT/IPS PWB. An overrun error was detected by hardware in the IIT/IPS PWB. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). - Page 45

003-328 IISS-ESS Communication Failure 9 RAP 003-329 IISS-ESS Communication Failure 10 RAP Receive interruption was detected by the IIT/IPS PWB.) A transmission failure occurred. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). Check the P/Js on the IIT/IPS PWB 11.3). - Page 46

003-330 IISS-ESS Communication Failure 11 RAP 003-331 IISS-ESS Communication Failure 12 RAP The Packet number of the received Message Packet is incorrect. The Message Length of the received Message Packet is incorrect. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). - Page 47

003-332 IISS-ESS Communication Failure 13 RAP 003-333 IISS-ESS Communication Failure 14 RAP The Check Code of the received Message Packet is incorrect.) A parity error was detected by the UART. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). Check the P/Js on the IIT/IPS PWB 11.3). - Page 48

003-334 IISS-ESS Communication Failure 15 RAP 003-335 IISS-ESS Communication Failure 16 RAP A framing error was detected by the UART. An overrun error was detected by the UART. Procedure Procedure Check the P/Js on the IIT/IPS PWB 11.3). Check the P/Js on the IIT/IPS PWB 11.3). - Page 49

003-336 IISS-ESS Communication Failure 17 RAP 003-337 IISS-ESS Communication Failure 18 RAP After the header was recognized, it was detected that receiving was aborted. After restoring from Power Saver mode, there was no response to the Power On command sent to the IIT/IPS PWB within the specified time. Procedure Procedure Check the P/Js on the IIT/IPS PWB… - Page 50

003-338 IISS-ESS Communication Failure 19 RAP 003-339 IISS-ESS Communication Failure 20 RAP The driver detected an incorrect send parameter argument from the application. The establishment of PAR transmission failed. Procedure Procedure Disconnect and reconnect the IIT Cable. Disconnect and reconnect the IIT Cable. Check the P/Js on ESS PWB 9.2). - Page 51

003-340 IISS-ESS Communication Failure 21 RAP 003-341 IISS-ESS Communication Failure 22 RAP A PAR synchronization error during send occurred. A PAR transmission error during send occurred. Procedure Procedure Disconnect and reconnect the IIT Cable. Disconnect and reconnect the IIT Cable. Check the P/Js on ESS PWB 9.2). - Page 52

003-342 IISS-ESS Communication Failure 23 RAP 003-343 IISS-ESS Communication Failure 24 RAP The driver detected an incorrect receive parameter argument from the application. A PAR synchronization error during receive occurred. Procedure Procedure Disconnect and reconnect the IIT Cable. Disconnect and reconnect the IIT Cable. Check the P/Js on ESS PWB 9.2). - Page 53

003-702 Different magnification, for surface and back RAP 003-750 Book Duplex-Insufficient Docs RAP Different magnification, for surface and back. No sheets are stored in the setting conditions. Procedure Procedure Change settings so that magnification is the same for both sides of the same document. A menu setup is incorrect. - Page 54

003-751 Under PANTHER Capacity (Scan) RAP 003-752 Cannot scan over 600DPI RAP The processed data is too small (the specified range for the document is too small). The selected resolution was too large for scanning mixed size originals using the document feeder. - Page 55

003-753 Cannot scan over 300DPI RAP 003-754 S2X Recovery RAP The selected resolution was too large for scanning mixed size originals using the document There is a recoverable S2X error. feeder. Initial Actions Procedure Power Off/On A menu setup is incorrect. Refer customer to following User Guide headings: Procedure •… - Page 56

003-755 S2X Command Error RAP 003-756 Blank Originals RAP There is an S2X command error. No image data was scanned from the documents. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Ask customer to cancel and rerun the job if the error did not clear after the power off/on. Check if the document is comprised of blank sheets, or if the front and back of the documents are correct. - Page 57

003-757 Cannot scan over 400DPI RAP 003-760 Scan Settings Error RAP Non-scannable 400dpi or more resolution detected after DADF Mix Duplex Mode Job is Invalid Scan Job Parameter. accepted. Procedure Procedure Abort job, change parameters and repeat operations. Change to 300dpi or less resolution for scan or change the job to that scannable with Non- Mixed mode. - Page 58

003-761 Incorrect Paper Tray Size RAP 003-763 Adjustment Chart Not Found RAP When the Cover Content Tray or Separator + N set Tray is selected in Auto Paper Selection When Automatic Gradation Correction was executed, the patch for position detection on the the paper size is different from that in the Cover Tray or the Transparency Tray. - Page 59

003-764 Image Overlay RAP 003-780 FAX Scan Compression Error RAP There is an image overlay problem. Compression of scanned data was unsuccessful. Initial Actions Procedure Power Off/On Ask customer to lower the resolution or reduction/enlargement ratio. Or try to break down the size of the original. Procedure Ask customer to verify the job setup and rerun the job. - Page 60

003-795 AMS Limit Error RAP 003-930 300 DPI Scan RAP After auto document detection in Auto Reduce/Enlarge, the Reduce/Enlarge ratio did not fall Cannot scan over 300 DPI. within the specified range (25%~400%). Procedure Procedure Scan at 300 dpi or lower. Ask customer to set the document size manually or change reduction/enlargement ratio. -

Page 61: Dpi Scan Rap

003-931 400 DPI Scan RAP 003-932 600 DPI Scan RAP Cannot scan over 400 DPI. Cannot scan 600 DPI. Procedure Procedure Scan 400 dpi or lower. Scan at under 600 dpi. Status Indicator Raps Launch Version February, 2008 003-931, 003-932 2-38 WorkCentre 5225, 5230…

- Page 62

003-933 300 DPI Scan RAP 003-934 400 DPI Scan RAP Next Documents Cannot scan over 300DPI. Next Documents Cannot scan over 400DPI. Procedure Procedure Scan at 300 dpi or lower. Scan at 400 dpi or lower. Launch Version Status Indicator Raps February, 2008 003-933, 003-934 WorkCentre 5225, 5230… - Page 63

003-935 600 DPI Scan RAP 003-940 Memory RAP Next Documents Cannot scan 600DPI. A scanner memory limit is reached. Procedure Procedure Scan at under 600 dpi. Power Off/On. If the problem persists replace the IIT/IPS PWB 11.3). Status Indicator Raps Launch Version February, 2008 003-935, 003-940… -

Page 64: Document Size Auto Detect Failure Rap

003-942 Document size Auto Detect Failure RAP 003-944 Image repeat count Failure RAP The document size cannot be automatically detected. No complete images are output using Automatic Size. Procedure Procedure Ask customer to set the document size manually. A menu setup is incorrect. Refer customer to User Guide heading Paper Size Settings. Launch Version Status Indicator Raps February, 2008…

-

Page 65: Every Direction Difference (Copy Aps) Rap

003-946 Every direction difference (Copy APS) RAP 003-947 Return Documents counts error RAP Paper size that does not support rotation was selected even though part of the image will be The number of documents returned by the user was less than the number of specified docu- cut off if it is not rotated.

-

Page 66: Return Documents Mismatch Rap

003-948 Return Documents mismatch RAP 003-952 Document Color Mismatch RAP A document that is different (document size/orientation and Color mode in ACS) from the doc- There is a color mismatch among returned documents. ument before document return was loaded. Procedure Procedure Ask customer to cancel the job, check job settings and rerun the job.

-

Page 67: Documents Size Exchange Error Rap

003-955 Documents size exchange error RAP 003-956 Documents size unknown error RAP When loading a document with Mixed Size Originals prohibited, a document of different size/ With Platen selected, the document size could not be identified. (APS, Auto Paper Selection orientation from the initial document was detected.

-

Page 68: No Aps Object Tray Rap

003-963 No APS object Tray RAP 003-965 ATS/APS No Paper (IIT Detect) RAP There was no APS (Auto Paper Selection) compatible tray that could supply paper for printing There was no paper in the tray for APS (Auto Paper Selection). without omitting part of the image.

-

Page 69: Ats/Aps No Destination (Iit) Rap

003-966 ATS/APS No Destination (IIT) RAP 003-967 DADF APS No Destination RAP There was no tray for APS (Auto Paper Selection). • Document size with DADF 8.5×11SEF Document size input not included. • Mix Size is not selected. Procedure • Magnification is variable.

-

Page 70: Punch Position Error Rap

003-968 Punch Position Error RAP 003-969 Punch Size Error RAP Cannot punch for the selected paper size. Cannot punch at selected position. (APS/Tray selection common) Procedure Procedure To designate appropriate Punch position or cancel Punch and restart the job. appropriate posi- To designate the proper Punch position or cancel Punch and restart the job.

-

Page 71: Fax Line Memory Overflow Rap

003-970 FAX Line Memory Overflow RAP 003-971 Prevention Code Detect RAP Document size exceeds scanning capacity. Prevention code detect with the right to cancel. Procedure Procedure A menu setup is incorrect. Refer customer to following User Guide headings: This document cannot be copied; press Cancel / Continue button on panel. •…

-

Page 72: Maximum Stored Page Over Flow Rap

003-972 Maximum Stored Page Over Flow RAP 003-973 Every direction difference RAP The number of scanned pages stored exceeded the maximum number set in the system data. Rotation is not available even though the orientation of the document and the image are differ- ent and part of the image will be omitted if it is not rotated.

-

Page 73: Next Original Specification Rap

003-974 Next Original Specification RAP 003-976 FAX Line Memory Overflow (N up) RAP Scanning has been completed for all loaded documents. Document size exceeds scanning capacity. Procedure Procedure No action required. A menu setup is incorrect. Refer customer to following User Guide headings: •…

-

Page 74: Document Mismatch (Multiple Scan) Rap

003-977 Document Mismatch (Multiple Scan) RAP 003-978 Color Document Miss Match (Multi Scan) RAP The document size differs from the one set previously for the Bound Originals feature. Document Color Mismatch (a change of document in Multi Scan: Procedure 1. A change of documents during scanning a Bound Document/As Book/Poster A menu setup is incorrect.

-

Page 75: Staple Position Error Rap

003-980 Staple position error RAP 003-981 Staple size error RAP Stapling could not be done at the specified position. Stapling on Documents with different widths. Procedure Procedure A menu setup is incorrect. Refer customer to following User Guide headings: Ensure customer selects stapling only when documents are the same width. •…

-

Page 76: Iit Hdd Access Error Rap

003-982 IIT HDD Access Error RAP BSD-ON:3.1/6.2 There is a problem with IIT accessing the Hard Drive. Procedure Disconnect and reconnect the IIT/IPS PWB Harness. Check HDD electrical connections 9.2). If the problem persists reload Software (ADJ 9.3.1). If the problem persists perform Hard Disk Diagnostic Program.

- Page 77

Status Indicator Raps Launch Version February, 2008 003-982 2-54 WorkCentre 5225, 5230… - Page 78

005-121 CVT Feed Sensor On JAM RAP Replace the DADF Feed Motor 15.9). If the problem persists, replace the DADF PWB 15.3). BSD-ON:5.4/5.5 Replace the DADF PWB 15.3). After the first-out feed operation started (Feed Motor On (CW)) in Duplex mode, the DADF Feed Out Sensor did not turn On within the specified time. -

Page 79: Cvt Simplex/Side1 Pre-Registration On Jam Rap

005-122 CVT Simplex/Side1 Pre-Registration On JAM RAP Measure the voltage between the DADF PWB 15.3) P754-1 (+) and GND (-), and between P754-7 (+) and GND (-) (BSD 5.5 Flag 1). The voltage is approx. +24VDC. • After the Pre Feed operation started for the first sheet (DADF Feed Motor On (CW)) in Duplex or Simplex mode, the Pre-Registration Sensor did not turn On within the specified Replace the DADF PWB 15.3).

-

Page 80: Cvt Simplex/Side1 Registration Jam Rap

005-123 CVT Simplex/Side1 Registration JAM RAP Replace the DADF Feed Motor 15.9). If the problem persists, replace the DADF PWB 15.3). After pre-registration started (DADF Feed Motor On (CCW)), the Registration Sensor did not turn On within the specified time. Replace the DADF PWB 15.3).

-

Page 81: Cvt Registration Sensor Off Jam Rap

005-125 CVT Registration Sensor Off JAM RAP Replace the DADF Feed Motor 15.9). If the problem persists, replace the DADF PWB 15.3). After the Pre Registration Sensor turned Off during the Read operation, the DADF Registration Sensor did not turn Off within the specified time. Execute Component Control[005-026].

-

Page 82: Cvt Invert On Jam Rap

005-131 CVT Invert On JAM RAP Replace the DADF Registration Motor 15.9). If the problem persists, replace the DADF PWB 15.3). After the Registration Sensor turned On during Invert operation, the Invert Sensor did not turn On within the specified time. Replace the DADF PWB 15.3).

-

Page 83: Cvt Invert On Jam 2 Rap

005-132 CVT Invert On JAM 2 RAP Replace the DADF Registration Motor 15.9). If the problem persists, replace the DADF PWB 15.3). After the Read Speed Control operation started (Registration Motor On (CCW)), the Invert Sen- sor did not turn On within the specified time. Replace the DADF PWB 15.3).

-

Page 84: Cvt Invert Sensor Off Jam (Inverter) Rap

005-134 CVT Invert Sensor Off JAM (Inverter) RAP Replace the DADF Registration Motor 15.9). If the problem persists, replace the DADF PWB 15.3). After the Registration Sensor turned Off on inverting at Invert, the Invert Sensor did not turn Off within the specified time.

-

Page 85: Cvt Side2 Pre-Registration On Jam Rap

005-135 CVT Side2 Pre-Registration On JAM RAP Measure the voltage between the DADF PWB 15.3) P755-1 (+) and GND (-), and between P755-6 (+) and GND (-) (BSD 5.5 Flag 2). The voltage is approx. +24VDC. After the Invert operation started (Registration Motor On (CW)) at Invert, the DADF Pre Regis- tration Sensor did not turn On within the specified time.

-

Page 86: Cvt Side2 Registration On Jam Rap

005-136 CVT Side2 Registration On JAM RAP Replace the DADF Feed Motor 15.9). If the problem persists, replace the DADF PWB 15.3). After the DADF Pre Registration Sensor turned On at Invert, the DADF Registration Sensor did not turn On within the specified time. Execute Component Control[005-072].

-

Page 87: Cvt Invert Sensor Off Jam Rap

005-139 CVT Invert Sensor Off JAM RAP Measure the voltage between the DADF PWB 15.3) P755-1 (+) and GND (-), and between P755-6 (+) and GND (-) (BSD 5.5 Flag 2). The voltage is approx. +24VDC. After the Registration Sensor turned Off during the Read operation, the Invert Sensor did not turn Off within the specified time.

-

Page 88: Cvt Registration Sensor Off Jam (Invert) Rap

005-145 CVT Registration Sensor Off JAM (Invert) RAP Measure the voltage between the DADF PWB 15.3) P754-1 (+) and GND (-), and between P754-7 (+) and GND (-) (BSD 5.5 Flag 1). The voltage is approx. +24VDC. After the DADF Pre Registration Sensor turned Off at Invert, the Registration Sensor did not turn Off within the specified time.

-

Page 89: Cvt Pre Registration Sensor Off Jam Rap

005-146 CVT Pre Registration Sensor Off JAM RAP Repair the open circuit or short circuit. After the DADF Feed Out Sensor turned Off in 1 Sided mode, the DADF Pre Registration Sensor did not turn Off within the specified time. Measure the voltage between the DADF PWB 15.3) P755-1 (+) and GND (-), and After the DADF Registration Motor turned On in 2 Sided mode, the DADF Pre Registra-…

-

Page 90: Cvt Pre Registration Sensor Off Jam (Invert) Rap

005-147 CVT Pre Registration Sensor Off JAM (Invert) RAP Repair the open circuit or short circuit. After the DADF Registration Motor turned On at Invert, the DADF Pre Registration Sensor did not turn Off within the specified time. Measure the voltage between the DADF PWB 15.3) P755-1 (+) and GND (-), and between P755-6 (+) and GND (-) (BSD 5.5 Flag…

-

Page 91: Size Mismatch Jam On Mix-Size Rap

005-194 Size Mismatch Jam on Mix-size RAP Check the wire between J772 and J759 for an open circuit or a short circuit (BSD 5.1 Flag 3/Flag 4). The wire between J772 and J759 is conducting without an open circuit or In Mixed Size Originals, it was detected that the Fast Scan Direction size was different from the a short circuit.

-

Page 92: Cvt Size Mismatch Jam (No Mix) Rap

005-196 CVT Size Mismatch JAM (No Mix) RAP Measure the voltage between the DADF PWB P759-5 (+) and GND (-) (BSD 5.1 Flag Actuate the DADF Tray Size 2 Sensor with paper. The voltage changes. The second and subsequent documents are different size to the first document. Replace the DADF Tray Size 2 Sensor 15.10).

- Page 93

005-197 Prohibit Combine Size JAM RAP Measure the voltage between the DADF PWB P759-5 (+) and GND (-) (BSD 5.1 Flag Actuate the DADF Tray Size 2 Sensor with paper. The voltage changes. A prohibited size combination was detected. Replace the DADF Tray Size 2 Sensor 15.10). - Page 94

005-198 Too Short Size JAM RAP Measure the voltage between the DADF PWB P761-10 (+) and GND (-) (BSD 5.4 Flag 4). The voltage is approx. +5VDC. The system detected a document with a length shorter than 115mm in the Slow Scan Direction. Replace the DADF PWB 15.3). - Page 95

005-199 Too Long Size JAM RAP Check the connections of P/J781 and P/J761. P/J781 P/J761 are connected cor- The system detected a document with the following length in the Slow Scan Direction: rectly. • Simplex mode: 672.4mm or longer Connect P/J781 and P/J761. - Page 96

005-275 DADF ROM Download Error 005-275 DADF Error There is a download error in the DADF ROM PWB. There is a processing error in the DADF PWB. Procedure Procedure Switch off the power. Ensure the ROM is properly installed in the DADF PWB. Switch on the Switch off the power. - Page 97

005-280 DADF EPROM Failure RAP 005-284 DADF Auto Paper Selection Sensor Logic Failure The DADF-EEPROM failed during the Read/Write operation. The combinations of outputs from the DADF APS 1 Sensor, DADF APS 2 Sensor and DADF Initial Actions APS 3 Sensor are abnormal. •… - Page 98

005-285 DADF Nudger Lift Up Failure RAP Replace the DADF PWB 15.3). After the DADF Nudger Motor started reverse rotation, the DADF Nudger Sensor did not turn On within the specified time. Measure the voltage between the DADF PWB P761-3 (+) and GND (-) (BSD 5.4 Flag Actuate the DADF APS 2 Sensor with paper. - Page 99

Measure the voltage between the DADF PWB 15.3) P786-1 (+) and GND (-) (BSD 5.2 005-286 DADF Feed Out Sensor Failure RAP Flag 5). The voltage is approx. +24VDC. During document transport, before the DADF Feed Out Sensor turned Off, the DADF Pre Reg- istration Sensor turned Off. - Page 100

Replace the DADF PWB 15.3). Measure the voltage between the DADF PWB P761-12 (+) and GND (-) (BSD 5.4 Flag 3). Actuate the DADF Pre Registration Sensor with paper. The voltage changes. Replace the DADF Pre Registration Sensor 15.7). Replace the DADF PWB 15.3). - Page 101

005-305 CVT Feeder Cover Interlock Open (running) RAP 005-306 Tray Interlock Open RAP The system detected that the DADF Interlock was opened while the DADF was running (RUN/ Tray Interlock Open during DADF operation detected. SUSPEND). Procedure Initial Actions To ensure that the Tray is Closed. Check the connections between the Tray Interlock Sensor •… - Page 102

005-309 CVT L/H Interlock Open RAP 005-500 Downloader Failure RAP CVT L/H Interlock Open while running. Detected error while writing DADF-ROM. Cannot work normally because the contents of ROM have been erased. Procedure Procedure Check the following: connector cables (connecting Interlock Switch and DADF-PWBA), or DADF-PWBA. - Page 103

005-906 CVT Feed Sensor Static JAM RAP Paper remains on the DADF Feed Out Sensor. Initial Actions • Refer to BSD 5.4. • Remove the paper. Procedure Execute Component Control[005-205 DADF Feed Out Sensor]. Actuate the DADF Feed Out Sensor 15.9) with paper. - Page 104

005-907 CVT Pre-Registration Sensor Static JAM RAP Paper remains on the DADF Pre Registration Sensor. Initial Actions • Refer to BSD 5.4. • Remove the paper. Procedure Execute Component Control[005-206 DADF Pre Registration Sensor]. Actuate the DADF Pre Registration Sensor 15.7) with paper. - Page 105

005-908 CVT Registration Sensor Static JAM RAP 005-909 DADF Lead Sensor Static Jam Paper remains on the DADF Registration Sensor. Lead Reg Sensor On detected at the timing below: Initial Actions 1. Power On • Refer to BSD 5.4. 2. Feeder Cover Interlock Close •… - Page 106

005-910 DADF Out Sensor Static Jam 005-911 DADF Exit 1 Sensor Static Jam Out Sensor On detected at the timing below: Exit1 Sensor On detected at the timing below: 1. Power On 1. Power On 2. Feeder Cover Interlock Close 2. - Page 107

005-912 DADF Exit 2 Sensor Static Jam 005-913 CVT Invert Sensor Static JAM RAP Exit2 Sensor On detected at the timing below: Paper remains on the DADF Invert Sensor. Initial Actions 1. Power On • Refer to BSD 5.4. 2. Feeder Cover Interlock Close •… - Page 108

005-914 DADF APS1, 2, 3, Sensor Static Jam 005-915 CVT APS No1 Sensor Static JAM RAP APS1, 2, 3, Sensor On detected at the timing below: Paper remains on the APS Sensor 1. Initial Actions 1. Power On • Refer to BSD 5.4. 2. - Page 109

005-916 CVT APS No2 Sensor Static JAM RAP Paper remains on the APS Sensor 2. Initial Actions • Refer to BSD 5.4. • Remove the paper. Procedure Execute Component Control[005-219 DADF APS 2 Sensor]]. Actuate the DADF APS 2 Sensor with paper. - Page 110

005-917 CVT APS No3 Sensor Static JAM RAP 005-918 CVT Invert Sensor Static Jam RAP Paper remains on the APS Sensor 3. CVT Invert Sensor On detected at the timing below: Initial Actions 1. Power On • Refer to BSD 5.4. 2. - Page 111

005-919 DADF Tray Lift Up Failure RAP 005-940 DADF No Original Failure RAP The following detected: Removal of Documents detected. Procedure With the document being set, Level Sensor does not turn On or Bottom Snr does not turn Off in a specified time from start of Tray Lift Up. - Page 112

005-941 DADF Not Enough Documents Failure RAP 005-942 Doc fault loading on DADF RAP After all originals returned, shortage of documents detected. Due to too many document sheets, no documents could not be fed. Procedure Initial Actions Follow instructions on the UI Screen Reduce the number of sheets and repeat the operation. - Page 113

Repair the open circuit or short circuit. Measure the voltage between the DADF PWB 15.3) P786-1 (+) and GND (-) (BSD 5.2 Flag 5). The voltage is approx. +24VDC. Replace the DADF PWB 15.3). Replace the DADF Nudger Motor 15.6). If the problem persists, replace the DADF 15.3). - Page 114

010-313 Control (Center) Thermistor Failure RAP BSD-ON:10.1 The Control (Center) Thermistor has an open circuit. Initial Actions • Power OFF/ON Procedure Check the installation of the Fuser Unit. The Fuser Unit is securely installed. Install the Fuser Unit securely. Check the resistance of the Center Thermistor between P600-5 and P600-6 (BSD 10.1 Flag 2/Flag 3). - Page 115

010-314 Rear Thermistor Failure RAP BSD-ON:10.1 The Rear Thermistor has an open circuit. Initial Actions • Power OFF/ON Procedure Check the installation of the Fuser Unit. The Fuser Unit is securely installed. Install the Fuser Unit securely. Check the resistance of the Rear Thermistor between J600-2 and J600-4 (BSD 10.1 Flag Flag 3). - Page 116

010-318 Hot-Sagging Recovery Failure RAP BSD-ON:4.1/10.1 The Rear Thermistor detected that the machine does not recover from Hot-Sagging in time. Initial Actions • Power OFF/ON Procedure Check for paper on the Fuser. The Fuser has no paper wrapped round it. Remove the paper. - Page 117

010-320 Heat Roll Over Temperature Failure RAP BSD-ON:10.1 • The Control (Center) Thermistor detected a temperature higher than the specified value. • The Rear Thermistor detected a temperature higher than the specified value. Procedure NOTE: When [010-320] occurs, NVM[744-220 FuserOverTemp]=1. After repair, change it to NVM[744-220 FuserOverTemp]=0. - Page 118

010-327 Fuser On Time Failure RAP Replace the Fuser Unit 5.1). BSD-ON:10.1 Check the resistance of the Rear Thermistor between J600-2 and J600-4 (BSD 10.1 Flag • After the Main Lamp turned On during warm up, the Control Thermistor did not detect Flag 3)). - Page 119

010-398 Fuser Lock Failure RAP 010-420 Fuser Near end of life RAP BSD-ON:10.2 BSD-ON:10.3 The Fuser Fan failed. The Fuser is near end of life. Initial Actions Initial Actions • Power OFF/ON • Power Off/On • Clear away foreign substances and dust accumulated at the exhaust. Procedure Procedure Turn on the power. - Page 120

010-421 Fuser end of life RAP BSD-ON:10.2 The Fuser is near end of life. Initial Actions • Power Off/On • Clear away foreign substances and dust accumulated at the exhaust. Procedure Turn on the power. Visually check the rotation of the Fuser Fan. The Fuser Fan is rotating. Measure the voltage between the MCU PWB P/J408-2 (+) and GND (-) (BSD 10.2 Flag 1). - Page 121

Status Indicator Raps Launch Version February, 2008 010-421 2-98 WorkCentre 5225, 5230… - Page 122

012-132 (A-Finisher) Ent Sensor ON Jam Measure the voltage between Finisher PWB J8709-5 (+) and GND (-). Actuate the Fin- isher Entrance Sensor. The voltage changes. BSD-ON:12.3 Replace the Finisher Entrance Sensor 22.5). Finisher Entrance Sensor does not turn On within a specified time after receiving the Sheet Exit command (the sheet to be ejected has turned ON the IOT Exit Sensor 1). -

Page 123: A-Finisher) Compiler Exit Sensor Off Jam

012-151 (A-Finisher) Compiler Exit Sensor OFF Jam Go to Wirenet A-Finisher +5VDC and check the +5VDC circuit. BSD-ON:12.3 Measure the voltage between Finisher PWB J8709-2 (+) and GND (-). Actuate the Com- The Compile Exit Sensor does not turn Off within a specified time after it has turned On. pile Exit Sensor.

-

Page 124: A-Finisher) Compiler Exit Sensor On Jam

012-152 (A-Finisher) Compiler Exit Sensor ON Jam Go to Wirenet A-Finisher +24VDC and check the +24VDC circuit. If the circuit is OK, BSD-ON:12.3 replace the Finisher PWB 22.7). The Compile Exit Sensor does not turn On within a specified time after receiving the Sheet Exit Enter [012-013], measure the voltage between Finisher PWB J8705-2 (+) and GND (-).

-

Page 125: A-Finisher) Set Eject Jam

012-161 (A-Finisher) Set Eject Jam Repair the open or short circuit. BSD-ON:12.3 Measure the voltage between Finisher PWB J8709-3 (+) and GND (-). The voltage is In the Eject Motor’s ejecting operation, Eject Home Sensor ON was detected within a specified approx.

-

Page 126: A-Finisher) Stacker Tray Fail

Check the wires and connectors for an intermittent open or short circuit. If the problem 012-211 (A-Finisher) Stacker Tray Fail continues, replace the Finisher PWB 22.7). BSD-ON:12.8 Enter [012-054] and [012-056] alternately. The Eject Motor rotates. • Within a specified time after the Stacker Tray started lifting up, the Stack Height Sensor did not detect the lifting up of the Stacker Tray.

- Page 127

Enter [012-278]. Block and unblock the Stacker Stack Sensor 1 by rotating the actuator. The Enter [012-060] and [012-061] alternately. The Stacker Motor rotates. display changes. Check the connections of P/J8711 and P/J8736. P/J8711 P/J8736 are securely Check the connections of P/J8707 and P/J8722. -

Page 128: A-Finisher) Front Tamper Home Sensor On Fail

012-221 (A-Finisher) Front Tamper Home Sensor ON Fail Enter [012-020] and [012-023] alternately. The Front Tamper Motor rotates. BSD-ON:12.4 Check the connections of P/J8710, P/J8738A and P/J8738B. P/J8710 P/J8738A and P/J8738B are securely connected. During the moving of the Front Tamper, when the Front Tamper Home Sensor was Off, to the home position, the Front Tamper Home Sensor did not detected turning On within a specified Connect P/J8710, P/J8738A and P/J8738B…

-

Page 129: A-Finisher) Front Tamper Home Sensor Off Fail

012-223 (A-Finisher) Front Tamper Home Sensor OFF Fail Check the wires and connectors for an intermittent open or short circuit. If the problem continues, replace the Finisher PWB 22.7). BSD-ON:12.4 Enter [012-020] and [012-023] alternately. The Front Tamper Motor rotates. •…

-

Page 130: A-Finisher) Rear Tamper Home Sensor Off Fail

012-224 (A-Finisher) Rear Tamper Home Sensor OFF Fail Check the wires and connectors for an intermittent open or short circuit. If the problem continues, replace the Finisher PWB 22.7). BSD-ON:12.4 Enter [012-026] and [012-029] alternately. The Rear Tamper Motor rotates. •…

-

Page 131: A-Finisher) Eject Home Sensor On Fail

012-259 (A-Finisher) Eject Home Sensor ON Fail Check the connections of P/J8706 and P/J8741. P/J8706 P/J8741 are securely BSD-ON:12.6 connected. In the Eject Motor’s initializing operation and ejecting operation, one of the following is met. Connect P/J8706 P/J8741 securely. • With the Eject Home Sensor Off, the Eject Motor started rotating in reverse direction.

-

Page 132: A-Finisher) Rear Tamper Home Sensor On Fail

012-263 (A-Finisher) Rear Tamper Home Sensor ON Fail Enter [012-026] and [012-029] alternately. The Rear Tamper Motor rotates. BSD-ON:12.4 Check the connections of P/J8710, P/J8737A and P/J8737B. P/J8710, P/J8737A and P/J8737B are securely connected. During the moving of the Rear Tamper from when the Rear Tamper Home Sensor was Off to the home position, the Rear Tamper Home Sensor was not detected turning On within a speci- Connect P/J8710, P/J8737A and P/J8737B…

-

Page 133: A-Finisher) Eject Home Sensor Off Fail

012-280 (A-Finisher) Eject Home Sensor OFF Fail Check for an open or short circuit between J8706 and J8741. The wires between J8706 and J8741 are OK. BSD-ON:12.6 Repair the open or short circuit. In the Eject Motor’s initializing operation and ejecting operation, the Eject Motor had rotated forward for a time corresponding to a specified qty of pulses since the Eject Home Sensor was Measure the voltage between Finisher PWB J8706-13 (+) and GND (-), and between On, and then the motor stopped, but then the Eject Home Sensor was not detected turning Off.

-

Page 134: A-Finisher) Set Clamp Home Sensor On Fail

012-283 (A-Finisher) Set Clamp Home Sensor ON Fail Connect P/J8706 P/J8740 securely. BSD-ON:12.7 Check for an open or short circuit between J8706 and J8740. The wires between In the initialize operations each at Power On, when Interlock closed and at the start of a job, J8706 and J8740 are OK.

-

Page 135: A-Finisher) Set Clamp Home Sensor Off Fail

012-284 (A-Finisher) Set Clamp Home Sensor OFF Fail Connect P/J8706 P/J8740 securely. BSD-ON:12.7 Check for an open or short circuit between J8706 and J8740. The wires between In the initialize operations each at Power On, when Interlock closed and at the start of a job, J8706 andJ8740 are OK.

-

Page 136: A-Finisher) Stapler Fail

012-291 (A-Finisher) Stapler Fail Measure the voltage between Finisher PWB P/J8701-5 (+) and GND (-). Enter [012-046] and [012-047] alternately. The voltage changes. BSD-ON:12.5 Replace the Staple Assembly 22.4). Within a specified time after the Staple Motor started rotating in reverse direction, the Staple Head Home Sensor was never detected turning On.

-

Page 137: A-Finisher) Top Cover Interlock Open

012-301 (A-Finisher) Top Cover Interlock OPEN Go to Wirenet A-Finisher +24VDC and check the +24VDC circuit. If the problem contin- BSD-ON:12.1 ues, replace the Finisher PWB 22.7). The Top Cover Interlock Open was detected. Check the wires and connectors for an intermittent open or short circuit. If the problem contin- ues, replace the Finisher PWB 22.7).

-

Page 138: A-Finisher) Front Cover Interlock Open

012-302 (A-Finisher) Front Cover Interlock OPEN 012-903 (A-Finisher) Paper Remains at Compiler Exit Sensor BSD-ON:12.1 BSD-ON:12.3 The Front Cover Interlock Open was detected. • At Power On, the Compile Exit Sensor detected paper. Initial Actions • While the Main Motor was operating at initialization at Power On, the Compile Exit Sensor •…

-

Page 139: A-Finisher) Paper Remains At Ent Sensor

012-935 (A-Finisher) Paper Remains at Ent Sensor BSD-ON:12.3 • At Power On the Finisher Entrance Sensor detected paper. • While the Main Motor was operating at initialization at Power On, the Finisher Entrance Sensor detected paper. • When the Cycle down operation at the end of a job was complete, the Finisher Entrance Sensor was On.

-

Page 140: H-Transport Entrance Sensor Off Jam A Rap

012-111 H-Transport Entrance Sensor Off JAM A RAP Connect P/J8862 and J8987. BSD-ON:12.14 Check the wire between J8862 and J8987 for an open circuit or a short circuit (BSD After the H-Transport Entrance Sensor turned On, the H-Transport Entrance Sensor did not 12.14).

-

Page 141: H-Transport Entrance Sensor On Jam A Rap

012-112 H-Transport Entrance Sensor On JAM A RAP Connect P/J8862 and J8987. BSD-ON:12.14 Check the wire between J8862 and J8987 for an open circuit or a short circuit (BSD After the Engine Fuser Exit Sensor turned On, the H-Transport Entrance Sensor did not turn 12.14).

-

Page 142: H-Transport Entrance. Snr Off Jam B Rap

012-126 H-Transport Entrance. SNR OFF JAM B RAP Connect P/J8862 and J8987. BSD-ON:12.14 Check the wire between J8862 and J8987 for an open circuit or a short circuit (BSD After the H-Transport Entrance Sensor turned On, the H-Transport Entrance Sensor did not 12.14).

-

Page 143: H-Transport Entrance Sensor On Jam B Rap

012-131 H-Transport Entrance Sensor On JAM B RAP Connect P/J8862 and J8987. BSD-ON:12.14 Check the wire between J8862 and J8987 for an open circuit or a short circuit (BSD After the Engine Fuser Exit Sensor turned On, the H-Transport Entrance Sensor did not turn 12.2).

-

Page 144: H-Transport Entrance Sensor On Jam Rap

012-132 H-Transport Entrance Sensor On JAM RAP Connect P/J8862 and J8987. BSD-ON:12.14 Check the wire between J8862 and J8987 for an open circuit or a short circuit (BSD After the Engine Fuser Exit Sensor turned On, the H-Transport Entrance Sensor did not turn 12.14).

-

Page 145: Compile Exit Sensor Off Jam Rap

012-151 Compile Exit Sensor Off JAM RAP Connect P/J8879 and P/J8983. BSD-ON:12.16 Check the wire between J8879 and J8983 for an open circuit or a short circuit (BSD After the Compile Exit Sensor turned On, the Compile Exit Sensor did not turn Off within the 12.16).

-

Page 146: Compile Exit Sensor On Jam Rap

012-152 Compile Exit Sensor On JAM RAP Connect P/J8879 and P/J8983. BSD-ON:12.16 Check the wire between J8879 and J8983 for an open circuit or a short circuit (BSD After the H-Transport Exit Sensor turned On, the Compile Exit Sensor did not turn On within 12.16).

-

Page 147: Finisher Set Eject Jam Rap

012-161 Finisher Set Eject JAM RAP Measure the resistance of the Eject Motor between each point of J8878-1/3/4/6 (BSD 12.22). The resistance is approx. 2Ohm. BSD-ON:12.19/12.22 Replace the Eject Motor 23.11). After the Eject Motor turned On, the Compile No Paper Sensor did not turn Off within the spec- ified time.

-

Page 148: Stacker Tray Failure Rap

012-211 Stacker Tray Failure RAP Check the wire between J8874 and J8988 for an open circuit or a short circuit (BSD 12.24). The wire between J8874 and J8988 is conducting without an open circuit or BSD-ON:12.24 a short circuit. After Stacker Tray started descending, the Stack Height Sensor did not turn Off within the spec- Repair the open circuit or short circuit.

-

Page 149: Stacker Tray Upper Limit Failure Rap

012-212 Stacker Tray Upper Limit Failure RAP Repair the open circuit or short circuit. BSD-ON:12.24 Replace the Stacker Motor 23.7). If the problem persists, replace the Finisher PWB After the Stacker Tray started descending, the Stacker Upper Limit Sensor remained ON. 23.16).

-

Page 150: Stacker Tray Lower Limit Failure Rap

012-213 Stacker Tray Lower Limit Failure RAP Replace the Stacker Motor 23.7). If the problem persists, replace the Finisher PWB 23.16). BSD-ON:12.24 Replace the Finisher PWB 23.16). If the problem persists, replace the MCU PWB 9.1). Stacker descended lower than normal levels, below low limit height. Initial Actions •…

-

Page 151: Front Tamper Home Sensor On Failure Rap

012-221 Front Tamper Home Sensor On Failure RAP Check the wire between J8884 and J8984 for an open circuit or a short circuit (BSD 12.18). The wire between J8884 and J8984 is conducting without an open circuit or BSD-ON:12.18/12.19 a short circuit. After the Front Tamper started moving to the home position, the Front Tamper Home Sensor Repair the open circuit or short circuit.

- Page 152

012-223 Front Tamper Home Sensor Off Failure RAP Check the wire between J8884 and J8984 for an open circuit or a short circuit (BSD 12.18). The wire between J8884 and J8984 is conducting without an open circuit or BSD-ON:12.18/12.19 a short circuit. After the Front Tamper started moving away from the home position, the Front Tamper Home Repair the open circuit or short circuit. - Page 153

012-224 Rear Tamper Home Sensor Off Failure RAP Check the wire between J8883 and J8984 for an open circuit or a short circuit (BSD 12.18). The wire between J8883 and J8984 is conducting without an open circuit or BSD-ON:12.18/12.19 a short circuit. After the Rear Tamper started moving away from the home position, the Rear Tamper Home Repair the open circuit or short circuit. -

Page 154: Puncher Home Sensor On Fail

012-231 Puncher Home Sensor ON Fail BSD-ON:15 The Puncher Home Sensor did not turn ON within the specified time after the Puncher Motor started running. Initial Actions Check the following: • Puncher Home Actuator for deformation • Puncher Home Sensor for proper installation •…

-

Page 155: Booklet Folder Home Sensor On Fail

012-243 Booklet Folder Home Sensor ON Fail BSD-ON:12.17 Folder Home Sensor is not turned on after the lapse of 500ms from Motor ON while Booklet Knife is returning to Home. Initial Actions • The Folder Home Sensor for improper installation •…

- Page 156

012-249 Booklet Front Stapler Fail 012-259 Eject Home Sensor ON Failure RAP BSD-ON:12.17 BSD-ON:12.22 Booklet Staple Mot F cannot clinch properly; Booklet Staple Cam SW F detected not to turn on — Eject Motor operated in reverse motion with Eject Clamp Home Sensor OFF; this sensor not (return to Home position could not be completed) within designated time period after starting detected to turn on subsequently within designated time period reverse motion. -

Page 157: Eject Clamp Home Sensor On Failure Rap

012-260 Eject Clamp Home Sensor ON Failure RAP Connect P/J8878 and P/J8983. BSD-ON:12.22 Check the wire between J8878 and J8983 for an open circuit or a short circuit (BSD After the Eject Clamp started ascending, the Eject Clamp Home Sensor did not turn On within 12.22).

-

Page 158: Rear Tamper Failure Rap

Check the wire between J8878 and J8983 for an open circuit or a short circuit (BSD 012-263 Rear Tamper Failure RAP 12.22). The wire between J8878 and J8983 is conducting without an open circuit or BSD-ON:12.19 a short circuit. After the Rear Tamper started moving to the home position, the Rear Tamper Home Sensor did Repair the open circuit or short circuit.

-

Page 159: Booklet Folder Home Sensor Off Fail

Check the wire between J8883 and J8984 for an open circuit or a short circuit (BSD 012-265 Booklet Folder Home Sensor OFF Fail 12.18). The wire between J8883 and J8984 is conducting without an open circuit or When the Booklet Home moves from Home position, the Folder Home Sensor did not turn OFF a short circuit.

-

Page 160: Booklet Rear Stapler Fail

012-268 Booklet Rear Stapler Fail 012-269 Booklet Sub-CPU Communications Fail BSD-ON:12.27 Communications between the Finisher PWB and the Booklet PWB Failed Initial Actions Booklet Stapler Assembly (Rear), cannot clinch properly; Booklet Rear Staple Home Switch detected not to turn on (return to Home position could not be completed) within designated •…

-

Page 161: Eject Clamp Home Sensor Off Failure Rap

012-282 Eject Clamp Home Sensor Off Failure RAP Check the wire between J8878 and J8983 for an open circuit or a short circuit (BSD 12.22). The wire between J8878 and J8983 is conducting without an open circuit or BSD-ON:12.22 a short circuit. After the Eject Clamp started descending, the Eject Clamp Home Sensor did not turn Off within Repair the open circuit or short circuit.

-

Page 162: Set Clamp Home Sensor On Failure Rap

012-283 Set Clamp Home Sensor On Failure RAP Check the wire between J8878 and J8983 for an open circuit or a short circuit (BSD 12.22). The wire between J8878 and J8983 is conducting without an open circuit or BSD-ON:12.23 a short circuit. After the Set Clamp started operation, the Set Clamp Home Sensor did not turn On within Repair the open circuit or short circuit.

-

Page 163: Set Clamp Home Sensor Off Failure Rap

012-284 Set Clamp Home Sensor Off Failure RAP Check the wire between J8878 and J8983 for an open circuit or a short circuit (BSD 12.22). The wire between J8878 and J8983 is conducting without an open circuit or BSD-ON:12.22/12.23 a short circuit. After the Set Clamp completed operation, the Set Clamp Home Sensor did not turn Off within Repair the open circuit or short circuit.

-

Page 164: Stapler Failure Rap

012-291 Stapler Failure RAP Measure the voltage between the Booklet PWB P8894-5, P8895-12 (+) and GND (-) (BSD 12.26/27). The voltage is approx. +5VDC. BSD-ON:12.26/12.27 Replace the Booklet PWB 23.21). • After the Stapler Motor turned On (Forward rotation), the system did not detect that the Staple Head Home Sensor switched from Off to On within the specified time.

-

Page 165: Staple Move Sensor On Failure Rap

012-295 Staple Move Sensor On Failure RAP Check the wire between J8906 and J8992 for an open circuit or a short circuit (BSD 12.20). The wire between J8906 and J8992 is conducting without an open circuit or BSD-ON:12.20 a short circuit. •…

-

Page 166: Staple Move Sensor Off Failure Rap

012-296 Staple Move Sensor Off Failure RAP Connect the connectors. BSD-ON:12.20 Check the wire between J8906 and J8992 for an open circuit or a short circuit (BSD • After the Stapler started moving to the Staple Position and the Staple Move Sensor turned 12.20).

-

Page 167: Eject Cover Open

012-300 Eject Cover Open BSD-ON:12.12 Eject Cover Switch open was detected. Initial Actions • Ensure that the Eject Cover is down • Check Eject Cover Switch for improper installation • Check Eject Cover Switch connectors for connection failure • Check Actuator part for deformation Procedure Enter Component Control…

-

Page 168: Finisher Front Cover Open Rap

012-302 Finisher Front Cover Open RAP BSD-ON:12.12 The Finisher Front Cover is open. Initial Actions • power OFF/ON • Opening/closing of the Finisher Front Cover. Procedure Check opening/closing of the Finisher Front Cover. The Finisher Front Cover can be opened/closed. Reinstall the Finisher Front Cover correctly.

-

Page 169: Finisher H-Transport Cover Open Rap

012-303 Finisher H-Transport Cover Open RAP 012-334 Download Mode Failure RAP BSD-ON:12.14 Failure in previous download (abnormal termination during download); can only start in Down- load Mode upon turning power on. The Finisher H-Transport Cover is open. Procedure Initial Actions Download defective;…

-

Page 170: Download Failure Rap

012-500 Download Failure RAP 012-700 Punch Dust Nearly Full RAP Detected error while writing to Finisher ROM. Punch Dust Tray nearly full. Procedure Proper operation not available since ROM may have been erased. Empty the Punch Dust Tray. Procedure Retry download. If the problem continues, replace the FInisher ROM 23.16).

-

Page 171: Finisher H-Transport Entrance Sensor Static Jam Rap

012-901 Finisher H-Transport Entrance Sensor Static JAM BSD-ON:12.14 Paper remains on the H-Transport Entrance Sensor. Initial Actions • Remove foreign substances on the sensor. • Power OFF/ON Procedure Execute Component Control[012-190 H-Transport Entrance Sensor]. Actuate the H-Transport Entrance Sensor 23.4) with paper. The display changes. Check the connections of J8861 and J8987.

-

Page 172: Paper Remains At Compiler Exit Sensor Rap

012-903 Paper Remains at Compiler Exit Sensor RAP BSD-ON:12.16 Paper remains on the Compiler Exit Sensor. Initial Actions Remove foreign substances on the sensor. Power OFF/ON Procedure Execute Component Control[012-150 Compile Exit Sensor]. Actuate the Compiler Exit Sensor with paper. The display changes. Check the connections of J8868 and P/J8988.

-

Page 173: Compile Paper Sensor Static Jam Rap

012-905 Compile Paper Sensor Static JAM RAP BSD-ON:12.16 Paper remains on the Compile Paper Sensor. Initial Actions • Remove foreign substances on the sensor. • Power OFF/ON Procedure Execute Component Control[012-150 Compile Exit Sensor]. Actuate the Compiler Exit Sensor with paper. The display changes. Check the connections of J8868 and P/J8988.

-

Page 174: H-Transport Entrance Snr Static Jam B Rap

012-923 H-Transport Entrance SNR static JAM B RAP 012-935 Paper at Xport Entrance Sensor BSD-ON:12.14 BSD-ON:12.16 During standby, paper was detected by the H-Transport Entrance Sensor. Control logic reports paper at the Xport Entrance Sensor. Initial Actions Initial Actions Remove foreign substances on the sensor. •…

-

Page 175: Punch Waste Bin Missing Rap

012-949 Punch Waste Bin Missing RAP Punch Waste Bin Set Snr detected Punch Box to be missing. Initial Actions • Ensure that the Puncher Waste Bin is present and installed properly • The Puncher Waste Bin Set Sensor for improper installation •…

-

Page 176: Booklet Staple Move Home Snr On Fail Rap

013-210 Booklet Staple Move Home SNR ON Fail RAP 013-211 Booklet Staple Move Home SNR OFF Fail RAP BSD-ON:12.25 BSD-ON:12.25 Booklet Staple Move Home SNR does not turn on within designated time period Booklet Staple Move Home SNR does not turn off within designated time period Initial Actions Initial Actions Power Off/On…

-

Page 177: Booklet Staple Move Position Snr On Fail Rap

013-212 Booklet Staple Move Position SNR ON Fail RAP 013-213 Booklet Staple Move Position SNR OFF Fail RAP BSD-ON:12.25 Booklet Staple Move Position SNR does not turn off within designated time period Initial Actions Booklet Staple Move Position SNR does not turn on within designated time period Power Off/On Initial Actions Power Off/On…

-

Page 178: Booklet Fold Detect Fail Rap

013-220 Booklet Fold Detect Fail RAP 013-306 Booklet Safety SW Open RAP BSD-ON:12.17 BSD-ON:12.13 Upon turning power on, a problem is detected in Booklet Unit or Fold Unit Upon turning power on, a problem is detected in Booklet Unit or Fold Unit Initial Actions Initial Actions Power Off/On…

-

Page 179: Booklet Cover Open Rap

013-307 Booklet Cover Open RAP BSD-ON:12.13 Upon turning power on, a problem is detected in Booklet Unit or Fold Unit Initial Actions Ensure the Cover is closed Procedure Check the Booklet Cover Switch for the following: • wiring • connections •…

-

Page 180: Software Option (Hdd Error) Rap

016-211 Software Option (System Memory Low) RAP 016-210 Software Option (HDD Error) RAP One of the Software option functions cannot be executed due to insufficient System Memory One of the Software option functions cannot be executed due to a HDD error or the HDD is not capacity.

-

Page 181: Software Option (Page Memory Low) Rap

016-212 Software Option (Page Memory Low) RAP 016-213 Software Option (Printer PWB) RAP One of the Software option functions cannot be executed due to insufficient Page Memory BSD-ON:16.1 capacity. One of the Software option functions cannot be executed due to a PRT_CARD error or Initial Actions PRT_CARD not installed.

-

Page 182: Serial Number Mismatch Rap

016-214 Serial Number Mismatch RAP 016-215 Software Option RAP The Serial Numbers are not in sync. Functions such as scanner cannot be executed due to an option PWB error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Go to Check installation and electrical connections of PWBs on PL 9.1 9.2.

-

Page 183: Software Option Rap

016-216 Software Option RAP 016-217 Software Option RAP Functions such as scanner cannot be executed due to an option PWB error. Functions such as scanner cannot be executed due to an option PWB error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure…

-

Page 184: Ps Kit Not Exist For Xdod Rap

016-218 PS KIT Not Exist for XDOD RAP 016-219 Software Option RAP Functions such as scanner cannot be executed due to an option PWB error. Functions such as scanner cannot be executed due to an option PWB error. Initial Actions Initial Actions Power Off/On Power Off/On…

-

Page 185: S2X Unrecoverable Error Rap

016-220 S2X Unrecoverable Error RAP 016-221 S2X Communication Error RAP Unrecoverable error sent by S2X. S2X communication error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure If operation is not normal, replace S2X board. If operation is not normal, replace S2X board. Status Indicator Raps Launch Version February, 2008…

-

Page 186: S2X Self-Diag Error Rap

016-222 S2X self-diag error RAP 016-223 S2X SDRAM Error RAP S2X self-diag error. S2X SDRAM Error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure If operation is not normal, replace S2X board. Remove then reinsert SDRAM memory to check for proper install. If the problem continues, replace S2X PWBA.

-

Page 187: S2X Pci Reg Error Rap

016-224 S2X PCI Reg Error RAP 016-225 S2X ROM CheckSum Error RAP S2X failed to access Internal PCI space. S2X failed in ROM Checksum test. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Remove then reinsert SDRAM memory to check for proper install. If the problem continues, Replace S2X board.

-

Page 188: S2X Iit Connection Error Rap

016-226 S2X IIT Connection Error RAP 016-227 S2X DDR Error RAP S2X cannot detect Video Clock sent from IIT. S2X failed in Internal DDR Memory Write/Read Test. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure (1) Check IISS-S2X cable for disconnection. Replace S2X board.

-

Page 189: S2X Image Processing Error Rap

016-228 S2X Image Processing Error RAP 016-240 S2X NVM CheckSum Fail RAP S2X failed in comparison of expected value of High-compression processing result obtained by S2X failed in NVM Checksum test. using Internal Test Pattern. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure…

-

Page 190: Ssmm Job Log Full Rap

016-310 ssmm Job Log Full RAP 016-311 Scanner Install RAP Job log file is not obtained from external application (AWAYS) and the files over specified limit The system detected that the scanner is not installed. (280 files) are stored. Procedure Initial Actions Check the electrical connections between the IIT and the ESS.

-

Page 191: Iit Interface Rap

016-315 IIT Interface RAP 016-316 Page Memory Not Detected RAP BSD-ON:6.2 The system detected that the Page Memory (Standard) of the scanner was not installed. Initial Actions An error was detected in the IF between the IIT and the IOT. Power Off/On Procedure Check the connection of each connector between the IIT and the IOT.

-

Page 192: Page Memory Error- Standard Rap

016-317 Page Memory Error- Standard RAP 016-318 Page Memory Error- Option RAP The system detected an error in the Page Memory (Standard) of the scanner. The system detected an error in the Page Memory (Option) of the scanner. Initial Actions Initial Actions Power Off/On Power Off/On…

-

Page 193: Fax Module Error Rap

016-321 Fax Module Error RAP 016-322 JBA Account Full RAP An error was detected at System Check Fax. The accumulated accounting data in Job Based Accounting reached the specified value (15000). Initial Actions Procedure Power Off/On Switch the power off then on 2 minutes after the job is attempted (after an external Accounting Server has read the accounting data).

-

Page 194: Scheduled Image Overwrite Rap

016-323 Scheduled Image Overwrite RAP 016-324 B Formatter Fatal Error RAP Scheduled Image Overwrite. An internal formatting error occurred. Procedure NOTE: Unrecoverable error was detected within Fax Send image conversion area B-Formatter task from extended mailbox in “Multi-Send using Job Flow Indication” or “UI Multi-Send”. Wait for the completion of Scheduled Image Overwrite to cancel operation, turn Power OFF/ Initial Actions Power Off/On…

-

Page 195: Ess Systemmemory Fail-1 Rap

016-330 ESS SystemMemory Fail-1 RAP 016-332 ESS SystemMemory Fail-3 RAP Capacity of Slot1 loaded memory is out of spec. Capacity of Slot1 and Slot2 loaded memory is out of spec. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Remove/insert ESS DDR DIMM #1.

-

Page 196: Ess Programrom Fail-1 Rap

016-335 ESS ProgramROM Fail-1 RAP 016-336 ESS ProgramROM Fail-2 RAP Program ROM2 CheckSum is not correct. Program ROM1 Write Command failure. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Replace ESS ROM DIMM #2 9.2). If the problem continues, replace ESS PWB 9.2).

-

Page 197: Ess Programrom Fail-3 Rap

016-337 ESS ProgramROM Fail-3 RAP 016-338 ESS FontROM Fail-1 RAP Program ROM2 Write Command failure. OnBoard loaded Font ROM ID is out of spec. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Remove/insert ESS ROM DIMM #2. If the problem continues, replace ESS ROM DIMM #2 Replace Print Kit.

-

Page 198: Ess Fontrom Fail-2 Rap

016-339 ESS FontROM Fail-2 RAP 016-340 ESS FontROM Fail-3 RAP Slot1 loaded Font ROM ID is out of spec. Slot2 loaded Font ROM ID is out of spec. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Perform the following: Remove/insert ESS FontROM DIMM #2.

-

Page 199: Ess Fontrom Fail-4 Rap

016-341 ESS FontROM Fail-4 RAP 016-342 ESS RTC Failure RAP Slot2 loaded Font ROM CheckSum is out of spec. RTC time range is out of the specified range. (Ex. 13 month 36 day) Time does not go on. Initial Actions Initial Actions Power Off/On Power Off/On…

-

Page 200: Ess Nv-Memory Failure Rap

016-345 ESS NV-Memory Failure RAP 016-347 ESS PageMemory Failure RAP Initial address data is 0x00. Slot2 loaded memory capacity is out of spec. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Replace the NVM PWB (PL xxx). If the problem continues, replace ESS PWB 9.2).

- Page 201

016-348 ESS PageMemory Failure-2 RAP 016-350 ESS SEEP-ROM Failure-1 RAP W/R/V test error for Page Memory. Product ID cannot be obtained. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Check the Page Memory connection. If the problem continues, replace PageMemory (Option) Check SEEPROM connection for bent pins. - Page 202

016-351 ESS SEEP-ROM Failure-2 RAP 016-360 ESS UI Failure-1 RAP W/R/V test error. PCI Config space W/R/V test error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Check SEEPROM connection for bent pins. Check Controller Board/BP Board Cable connec- Remove/insert UI Card. - Page 203

016-362 ESS UI Failure-2 RAP 016-363 ESS LyraCard Failure RAP UI Communication error VRAM W/R/V test error if Long Boot Mode is entered, Command/Sta- PCI Config space W/R/V test or internal register W/R/V test error. tus line would be normal. Initial Actions Initial Actions Power Off/On… - Page 204

016-364 ESS USB2.0 Host Failure RAP 016-365 ESS USB2.0 Device Failure RAP PCI Config space W/R/V test or internal register W/R/V test error. PCI Config space W/R/V test or internal register W/R/V test error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure… - Page 205

016-366 ESS HDD Failure-1 RAP 016-367 ESS HDD Failure-2 RAP IDE Controller error (ideDrv equivalent). HDD W/R/V test error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Perform the following in order: Perform the following in order: • Remove/insert HDD Cable •… - Page 206

016-368 ESS Torino Failure RAP 016-369 ESS S2X PWB Failure RAP PCI Config space W/R/V test or internal register W/R/V test error. PCI Config space W/R/V test error. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Perform the following in order: Perform the following in order: •… - Page 207

016-400 802.1x Authentication Failure RAP 016-401 802.1x EAP Type Not Supported RAP (1) User name or password set for M/C is not correct. (1) Fail signal informing that authentication method set for M/C cannot be processed is received from “Authentication device” physically network-connected with M/C. (2) Switch setting of “Authentication device”… - Page 208

016-402 802.1x Authentication Failure by Timing Out RAP 016-403 802.1x Certificate Failure RAP No response signal is received from “Authentication device” physical network-connection with (1) Root certificate is not stored in M/C. the M/C. Authentication timeout. (2) M/C root certificate and authentication server certificate are not the same. Procedure Procedure Check switch setting and network connection of “Authentication device”… - Page 209

016-404 802.1x Inside Failure RAP 016-450 SMB Host Name Duplicated RAP (1) Internal error occurs with 802.1xSupplicant function of M/C. A PC of the same host name exists on the network. Initial Actions (2) Illegal protocol signal is received from authentication server. Power Off/On Procedure To retry the operation. - Page 210

016-453 Dynamic DNS — IPv6 NG RAP 016-454 DNS Dynamic Update RAP Dynamic DNS — IPv6 NG. Unable to retrieve the IP address from DNS. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure 1 Check if DNS server address has been properly set to the device Check the DNS confutation and IP address of the retrieve setting. - Page 211

016-455 SMTP Server Time-out RAP 016-456 SMTP time asynchronous RAP There is no response from the SMTP server within the specified time (60sec). A standard time synchronized source message and an asynchronous message was received from the SMTP server. Initial Actions Initial Actions Power Off/On Power Off/On… - Page 212

016-500 DIMM RAP 016-501 S2X RAP A definition is not available at time of publication. A definition is not available at time of publication. Procedure Procedure A procedure is not available at time of publication. A procedure is not available at time of publication. Launch Version Status Indicator Raps February, 2008… - Page 213

016-502 ROM Write RAP 016-503 SMTP Redirector RAP There is a ROM writing failure in the Controller. The Redirector cannot resolve the SMTP (Simple Mail Transfer Protocol) Server address. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Remove and replace the DIMM 9.2) Refer customer to System Administrator Guide headings •… - Page 214

016-504 Redirector POP Server RAP 016-505 Redirector POP Authentication RAP The Redirector cannot resolve the POP (Post Office Protocol) Server address. The Redirector cannot pass POP (Post Office Protocol) authentication. Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure Specify the correct POP Server name or specify the IP address. - Page 215

016-513 XPS Error RAP 016-514 XPS Error RAP Invalid Schema, parameter error, XPS file breakage and XPS decomposer internal error Invalid Schema, parameter error, XPS file breakage and XPS decomposer internal error occurs while in XPS Bridge is processing. occurs while in XPS Bridge is processing. Procedure Procedure Print using printer driver (ART-EX,PCL etc.) from XPS Viewer. - Page 216

016-515 XPS Short of Memory RAP 016-516 XPS PrintTicket Description Error RAP Memory shortage is detected in XPS Bridge processing. Procedure Check if there is any problem in usage of the application for submitting print job and print Procedure request content. Change print mode to “Standard”… - Page 217

016-517 PS Booklet Illegal Color Mode Change RAP 016-519 Device DV — Reached Limit RAP PSDecomp detects change of ProcessColorModel or resolution/bi-tone/con-tone parameter Device Document Volume — Reached Limit. while in interpretation of job with Booklet designation. Procedure Procedure Change the maximum number of documents that can be printed. Rewrite PostScript file not to change Page Device ProcessColorModel during operation. - Page 218

016-522 LDAP RAP 016-523 LDAP RAP There is a LDAP (Lightweight Directory Access Protocol) server SSL (Secure Socket Layer) There is a LDAP (Lightweight Directory Access Protocol) server SSL (Secure Socket Layer) authentication error. An SSL Client Certificate could not be acquired. authentication error. - Page 219

016-524 LDAP RAP 016-525 LDAP RAP There was a LDAP server SSL authentication error. The server certificate is not yet valid. There was a LDAP server SSL authentication error. The server certificate has expired Initial Actions Initial Actions Power Off/On Power Off/On Procedure Procedure… - Page 220

016-526 LDAP RAP 016-527 LDAP RAP There was a LDAP server SSL authentication error. The server name does not match the cer- There was a LDAP server SSL authentication error. There was an SSL authentication internal tificate. error. Initial Actions Initial Actions Power Off/On Power Off/On… - Page 221

016-533 LDAP RAP 016-534 LDAP RAP There was a Kerberos server authentication protocol error. The machine and the Kerberos There was a Kerberos server authentication protocol error. The realm assigned to the machine server clocks have a time difference that exceeds the Kerberos server clock skew value. does not exist on the Kerberos server or the machine is not connecting to the Kerberos server address. - Page 222

016-539 LDAP RAP 016-574 Host Name Error RAP There was a Kerberos server authentication protocol error. A failure in resolving a problem with a host name in FTP scan Initial Actions Procedure Power Off/On Check the connection to DNS. Or check that the destination server name is entered on DNS. Procedure This error was generated by the software. - Page 223

016-575 DNS Server Error in FTP RAP 016-576 Server Connection Error in FTP RAP In FTP scan, the server was not found on DNS. In FTP scan, there is a problem with the connection to the server. Procedure Procedure Set DNS address. Check that the destination FTP server and this machine are set up so that they can communi- cate with each other on the network. - Page 224

016-577 FTP Service RAP 016-578 Login/Password Error RAP FTP Service has a problem. A login name or password error in FTP scan. Procedure Procedure Check the following: Check the login name (user name) and password are correct. • FTP Service is activated •… - Page 225

016-579 Scanning Picture Error RAP 016-580 File Name Acquisition Failure RAP There is a problem with the place to save images scanned in FTP scan. A failure in acquiring a file name/folder on the FTP scan server. Procedure Procedure Check that the scanned-images saving place on the FTP scan server is correct. Check the right to access the FTP scan server. - Page 226