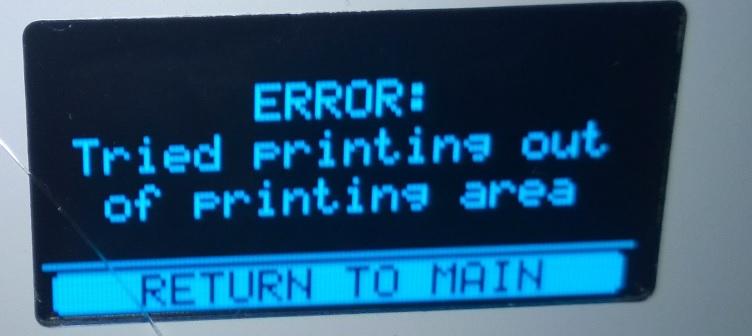

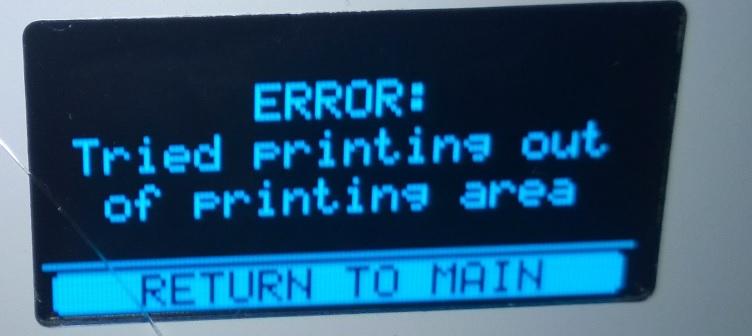

Over the last few weeks I was getting this error occasionally and even worse — every few minutes of printing the print head would move to the edge of the print and then come back to the print and continue.

I tried many things — changing SD cards (no difference) cleaning the SD card. Swapping ribbon cables. Finally I cleaned out the SD card reader inside the printer and that fixed it instantly. While cleaning I noticed a large hair about 2cm long inside there. But I also used a wooden toothpick dipped in alcohol to clean each of the 10 or so contacts. One at a time. Carefully.

I think I probably could have done it without taking it apart so next time I will try that. Blowing hard in the slot probably would have fixed the problem. But if you do take it apart there is one tricky step. So do the tricky part first. First remove the white knob (not the transparent cylinder that the knob goes in). { edit — push the knob out from behind as shown in Erin’s post below } Once it is out you will see a metal nut. Remove that nut! That’s the tricky part. Everything else was pretty obvious. If you really want detailed directions you can get them here in this pdf with pictures:

https://github.com/Ultimaker/Ultimaker2/blob/master/um2%20assembly%20manual%20V1.1%20_english.pdf

Edited March 14, 2017 by Guest

Доброго дня всем.

С недавних пор являюсь, относительно счастливым обладателем Sanjiuprinter Z360, клона Ultimaker 2, но с двумя экструдерами.

Относительно счастливый по причинам некоторых косяков и недоделок китайских товарищей….

В целом все проблемы пройдены, что касалось механики. Но на рисовалась проблема-при печати все чаще и чаще выскакивает ошибка: Tried printing out of printing area.

При изучения гугла, данная ошибка попалась только на форуме Ultimaker-а, где народ подозревал карты памяти, картридеры и наводки на проводах.

Сталкивался ли кто либо, из вас с данной ошибкой, и как методы её устранения, были найдены.

Всем в заранее спасибо за помощь.

The UltiMaker S7 is built on the success of the UltiMaker S5 and its design decisions were heavily based on feedback from customers.

So what’s new?

The obvious change is the S7’s height. It now includes an integrated Air Manager. This filters the exhaust air of every print and also improves build temperature stability. To further enclose the build chamber the S7 only has one magnetically latched door.

The build stack has also been completely redesigned. A PEI-coated flexible steel build plate makes a big difference to productivity. Not only do you not need tools to pop a printed part off. But we also don’t recommend using or adhesion structures for UltiMaker materials (except PC, because…it’s PC). Along with that, 4 pins and 25 magnets make it easy to replace the flex plate perfectly – even with one hand.

The re-engineered print head has an inductive sensor which reduces noise when probing the build plate. This effectively makes it much harder to not achieve a perfect first layer, improving overall print success. We also reversed the front fan direction (fewer plastic hairs, less maintenance), made the print core door magnets stronger, and add a sensor that helps avoid flooding.

The UltiMaker S7 also includes quality of life improvements:

Reliable bed tilt compensation (no more thumbscrews) 2.4 and 5 GHz Wi-Fi A 1080p camera (mounted higher for a better view) Compatibility with 280+ Marketplace materials Compatibility with S5 project files (no reslicing needed) And a whole lot more

Curious to see the S7 in action?

We’re hosting a free tech demo on February 7.

It will be live and you can ask any questions to our CTO, Miguel Calvo.

Register here for the Webinar

Доброго дня всем.

С недавних пор являюсь, относительно счастливым обладателем Sanjiuprinter Z360, клона Ultimaker 2, но с двумя экструдерами.

Относительно счастливый по причинам некоторых косяков и недоделок китайских товарищей….

В целом все проблемы пройдены, что касалось механики. Но на рисовалась проблема-при печати все чаще и чаще выскакивает ошибка: Tried printing out of printing area.

При изучения гугла, данная ошибка попалась только на форуме Ultimaker-а, где народ подозревал карты памяти, картридеры и наводки на проводах.

Сталкивался ли кто либо, из вас с данной ошибкой, и как методы её устранения, были найдены.

Всем в заранее спасибо за помощь.

Application Version

Cura 3.3.1

Platform

Mac OS 10.13.4

Printer

Ultimaker 2+

STL file 3v3v1_clay_stamp_4.stl.zip

3v3v1_clay_stamp_4.stl.zip

included.

Steps to Reproduce

Open Cura 3.3.1, slice the STL file, then try to print the produced gcode file on an Ultimaker 2+. This yields the error message “tried printing out of printing area” even when the object is only a few cm in size.

This time open Cura 3.2.1, slice the STL file, then print the gcode file without problem on the same Ultimaker 2+.

Actual Results

Error message appears on printer after giving it the gcode file made by Cura 3.3.1, and job does not print. The Cura 3.2.1 gcode file prints fine.

Expected results

I would expect both versions to print fine.

Additional Information

Go to prusa3d

SlicerPE: Printing out of area. Should I get a warning?

Should SlicerPE give me a warning when I’m printing out of bounds, or is there a way to check before I send a job to the printer?

I just got my MK3 and put it together Friday and I’m trying to figure out this software stack.

I threw a SpannerHands spool base into SlicerPE and figured I could just hit «Send to printer» and it didn’t give me any errors. 11 hours later, it stopped when it tried to print out of area.

Should I be getting a warning in the slicer software, or is there any way to check the print area before printing?

I’ve got an MK3, Slic3rPE has the printer set as Original Prusa i3 MK3, and OctoPrint has my printer profile manually configured (250x210x210, with -5mm min on the Y custom bounding box).

Here are a few pictures:

-

It printed flawlessly until it got to the front of the print bed, and it looks like it just blobbed up a bunch of filament at the front.

-

Edge-on view showing front edge of print area

-

Clearer view of the front edge «bunching up» — it should be continuing to angle forward, not turning up in a sharp vertical edge.

-

-

Here’s what Slic3rPE shows. It’s clearly too long in the Y dimension, but I didn’t think to visually check.

I’m curious if there’s an way for the tool to tell me when I’m out-of-bounds, because I may not notice it on a visual inspection if it’s just a couple of layers out (unlike this obvious mistake).

I’m pretty sure I can just rotate this object 90 degrees and print the long end on the X-axis, but I figured I’d reach out and ask if there’s something wrong with my process, since this is all new to me.

Also, am I doing something wrong here: Slic3r let me select the MK3 as my printer, so I’m assuming it used sane settings, but OctoPrint required me to manually input the printer dimensions. I went with 250(X)x210(Y)x210(Z), and then -5mm on the Y-axis min in the Custom Bounding Box area so it can print the starter line. For Axes speeds, I went with 6000, 6000, 200, 300. I based these settings on a forum post that I ran across, so they may not be exactly right.

Any help would be appreciated. This is only my third print, so I’m expecting many failures in the future

Whenever I try to print via SD card (since I get «firmware unresponsive» after a couple hours when I print via USB), I get the following error on the printer’s LCD:

«Error: Tried printing out of printing area»

No, I didn’t, and nowhere in my print does the toolpath exit the area. When I enter the commands in the gcode file one by one, it works absolutely fine. Yet from SD card, it fails. It fails immediately after homing all the axes, not sure at what command. It prints fine over USB till the firmware becomes unresponsive.

Do you want me to attach the gcode file?

Application Version

Cura 3.3.1

Platform

Mac OS 10.13.4

Printer

Ultimaker 2+

STL file 3v3v1_clay_stamp_4.stl.zip

3v3v1_clay_stamp_4.stl.zip

included.

Steps to Reproduce

Open Cura 3.3.1, slice the STL file, then try to print the produced gcode file on an Ultimaker 2+. This yields the error message “tried printing out of printing area” even when the object is only a few cm in size.

This time open Cura 3.2.1, slice the STL file, then print the gcode file without problem on the same Ultimaker 2+.

Actual Results

Error message appears on printer after giving it the gcode file made by Cura 3.3.1, and job does not print. The Cura 3.2.1 gcode file prints fine.

Expected results

I would expect both versions to print fine.

Additional Information

Go to prusa3d

SlicerPE: Printing out of area. Should I get a warning?

Should SlicerPE give me a warning when I’m printing out of bounds, or is there a way to check before I send a job to the printer?

I just got my MK3 and put it together Friday and I’m trying to figure out this software stack.

I threw a SpannerHands spool base into SlicerPE and figured I could just hit «Send to printer» and it didn’t give me any errors. 11 hours later, it stopped when it tried to print out of area.

Should I be getting a warning in the slicer software, or is there any way to check the print area before printing?

I’ve got an MK3, Slic3rPE has the printer set as Original Prusa i3 MK3, and OctoPrint has my printer profile manually configured (250x210x210, with -5mm min on the Y custom bounding box).

Here are a few pictures:

-

It printed flawlessly until it got to the front of the print bed, and it looks like it just blobbed up a bunch of filament at the front.

-

Edge-on view showing front edge of print area

-

Clearer view of the front edge «bunching up» — it should be continuing to angle forward, not turning up in a sharp vertical edge.

-

-

Here’s what Slic3rPE shows. It’s clearly too long in the Y dimension, but I didn’t think to visually check.

I’m curious if there’s an way for the tool to tell me when I’m out-of-bounds, because I may not notice it on a visual inspection if it’s just a couple of layers out (unlike this obvious mistake).

I’m pretty sure I can just rotate this object 90 degrees and print the long end on the X-axis, but I figured I’d reach out and ask if there’s something wrong with my process, since this is all new to me.

Also, am I doing something wrong here: Slic3r let me select the MK3 as my printer, so I’m assuming it used sane settings, but OctoPrint required me to manually input the printer dimensions. I went with 250(X)x210(Y)x210(Z), and then -5mm on the Y-axis min in the Custom Bounding Box area so it can print the starter line. For Axes speeds, I went with 6000, 6000, 200, 300. I based these settings on a forum post that I ran across, so they may not be exactly right.

Any help would be appreciated. This is only my third print, so I’m expecting many failures in the future