| No. | Код ошибки (SPN) | Код мигания | Неисправность Daewoo Novus |

|---|---|---|---|

| 1 | 18 | 2,2 | датчик давления топлива |

| 2 | 91 | 2,3 | педаль газа (АРР1) |

| 3 | 100 | 1,8 | датчик давления масла |

| 4 | 102 | 1,4 | датчик поступающего воздуха |

| 5 | 110 | 1,1 | датчик температуры охлаждающей жидкости |

| 6 | 132 | 2,6 | датчик расхода воздуха |

| 7 | 158 | 2,1 | аккумулятор VOLT |

| 8 | 171 | 1,5 | датчик температуры воздуха |

| 9 | 174 | 1,2 | датчик температуры топлива |

| 10 | 175 | 1,7 | датчик температуры масла |

| 11 | 190 | 4,4 | датчик скорости двигателя (частоты вращения |

| 12 | 597 | 2,8 | переключатель рабочего тормоза |

| 13 | 598 | 2,7 | переключатель сцепления |

| 14 | 602 | 2,9 | Круиз-контроль |

| 15 | 606 | 3,8 | обороты двигателя |

| 16 | 623 | 8,6 | низкое напряжение блока питания более 20 |

| 17 | 627 | 4,8 | источник питания |

| 18 | 647 | 7,2 | низкое напряжение блока питания более 7 |

| 19 | 723 | 10,6 | превышение скорости двигателя |

| 20 | 734 | 5,8 | Соленоид. Блок питания 1 и более |

| 21 | 735 | 5,9 | Соленоид. Блок питания 2 и более |

| 22 | 736 | 6,1 | Соленоид. Блок питания 3 и более |

| 23 | 737 | 6,2 | Соленоид. Блок питания 4 и более |

| 24 | 738 | 6,3 | Соленоид. Блок питания 5 и более |

| 25 | 739 | 6,4 | Соленоид. Блок питания 6 и более |

| 26 | 974 | 9,6 | дистанционный дроссель |

| 27 | 975 | 3,1 | модуль MWIS |

| 28 | 977 | 11,6 | тайм-аут сообщения ЕВС1 |

| 29 | 1072 | 7,7 | пониженное напряжение блока питания более 12 |

| 30 | 1073 | 7,9 | пониженное напряжение блока питания более 14 |

| 31 | 1208 | 3,3 | регулирование давления поступающего воздуха |

| 32 | 1209 | 3,4 | регулирование выхлопных газов |

| 33 | 1213 | 7,5 | пониженное напряжение блока питания более 10 |

| 34 | 1238 | 3,6 | Авто Т / М контроль |

| 35 | 1320 | 1,6 | датчик давления воздуха |

| 36 | 1322 | 10,4 | брак зажигания в разных цилиндрах |

| 37 | 1323 | 9,7 | брак зажигания цилиндра #1 |

| 38 | 1324 | 9,8 | брак зажигания цилиндра #2 |

| 39 | 1325 | 9,9 | брак зажигания цилиндра #3 |

| 40 | 1326 | 10,1 | брак зажигания цилиндра #4 |

| 41 | 1327 | 10,2 | брак зажигания цилиндра #5 |

| 42 | 1328 | 10,3 | брак зажигания цилиндра #6 |

| 43 | 1482 | 3,5 | Т/М контроль |

| 44 | 1485 | 3,9 | главный реле SCG |

| 45 | 1624 | 2,5 | скорость машины |

| 46 | 1639 | 11,5 | датчик скорости вентилятора |

| 47 | 520193 | 1,3 | датчик температуры поступающего воздуха |

| 48 | 520194 | 1,9 | переключатель многократного положения |

| 49 | 520195 | 2,4 | педаль газа (АРР2) |

| 50 | 520196 | 3,2 | контроль давления топлива MPROP |

| 51 | 520196 | 11,7 | контроль давления топлива MPROPHIGH |

| 52 | 520197 | 3,7 | CAN-В Line |

| 53 | 520198 | 4,1 | повышенный канал shut-off (отключение) |

| 54 | 520199 | 4,2 | датчик скорости двигателя(коленчатый вал) |

| 55 | 520200 | 4 3 | Датчик скорости двигателя |

| 56 | 520201 | 4,5 | ошибка хранения данных ЭСППЗУ в электронном блоке управления |

| 57 | 520202 | 4,6 | ошибка активации после включения электронного блока управления |

| 58 | 520203 | 4,7 | ошибка проверки PRV |

| 59 | 520204 | 4,9 | неисправность главного реле SCB |

| 60 | 520205 | 5,1 | неисправность главного реле ЕСМ |

| 61 | 520206 | 9,1 | CAN-ALine |

| 62 | 520207 | 5,2 | баланс цилиндра, цилиндр 1 |

| 63 | 520256 | 5,3 | баланс цилиндра, цилиндр 2 |

| 64 | 520257 | 5,4 | баланс цилиндра, цилиндр 3 |

| 65 | 520258 | 5,5 | баланс цилиндра, цилиндр 4 |

| 66 | 520259 | 5,6 | баланс цилиндра, цилиндр 5 |

| 67 | 520260 | 5,7 | баланс цилиндра, цилиндр 6 |

| 68 | 520262 | 6,6 | пониженное напряжение блока питания более 2 |

| 69 | 520262 | 8,3 | пониженное напряжение блока питания более 17 |

| 70 | 520263 | 6,7 | пониженное напряжение блока 3 |

| 71 | 520264 | 7,3 | пониженное напряжение блока питания более 8 |

| 72 | 520265 | 7,4 | пониженное напряжение блока питания более 9 |

| 73 | 520266 | 7,8 | пониженное напряжение блока питания более 13 |

| 74 | 520267 | 7,6 | пониженное напряжение блока питания более 11 |

| 75 | 520268 | 6,9 | пониженное напряжение блока питания более 5 |

| 76 | 520269 | 6,8 | пониженное напряжение блока питания более 4 |

| 77 | 520270 | 8,1 | пониженное напряжение блока питания более 15 |

| 78 | 520271 | 8,2 | пониженное напряжение блока питания более 16 |

| 79 | 520272 | 8,4 | пониженное напряжение блока питания более 18 |

| 80 | 520273 | 8,5 | пониженное напряжение блока питания более 19 |

| 81 | 520274 | 8,7 | пониженное напряжение блока питания более 21 |

| 82 | 520275 | 8,8 | пониженное напряжение блока питания более 22 |

| 83 | 520276 | 8,9 | пониженное напряжение блока питания более 23 |

| 84 | 520277 | 9,2 | пониженное напряжение блока питания более 24 |

| 85 | 520278 | 9,3 | пониженное напряжение блока питания более 25 |

| 86 | 520320 | 9,4 | пониженное напряжение блока питания более 26 |

| 87 | 520324 | 6,5 | пониженное напряжение блока питания более 1 |

| 88 | 520325 | 7,1 | пониженное напряжение блока питания более 6 |

| 89 | 520326 | 10,5 | слишком долго был открыт инжектор |

| 90 | 520327 | 10,7 | педаль газа(АРРЗ) |

| 91 | 520328 | 10,8 | контроль плавного зажигания Seg-0 |

| 92 | 520329 | 10,9 | контроль плавного зажигания Seg-1 |

| 93 | 520330 | 11,1 | контроль плавного зажигания Seg-2 |

| 94 | 520331 | 11,2 | контроль плавного зажигания Seg-3 |

| 95 | 520332 | 11,3 | контроль плавного зажигания Seg-4 |

| 96 | 520333 | 11,4 | контроль плавного зажигания Seg-5 |

| 97 | 520334 | 11,7 | давление поступающего воздуха plausibility |

| 98 | 520335 | 11,8 | температура поступающего воздуха plausibility |

| 99 | 520336 | 11,9 | температура охлаждающей жидкости plausibility |

| 100 | 520337 | 12,1 | температура масла plausibility |

| 101 | 520338 | 12,2 | давление топлива plausibility |

| 102 | 520339 | 12,3 | защита UDV-самая низкая величина “момента вращения” |

| 103 | 520340 | 12,4 | защита UDV-самая высокая величина “момента вращения” |

| 104 | 520341 | 12,5 | DCU |

See also: Daewoo trucks PDF workshop manuals;

Daewoo Ultra Novus

Engine Diagnostics

The engine diagnostics can be carried out by scanning the scan-200 or by checking the fault codes displayed on the instrument panel with a flashing control lamp with

Image of the engine.

We recommend that you use a diagnostic scanner asIt provides a quick and accurate check.

Diagnostics procedure

a) Turn the main Switch “on” position of the battery.

b) Ignition key-in position “ON”.

c) Engine does not It’s working.

d) Press the engine diagnostics button. (Hold 2 SEC).

e) The control lamp will start flashing on the instrument panel Image of the engine.

f) Check the fault codes, then turn the ignition key into the Position «OFF».

Display fault code

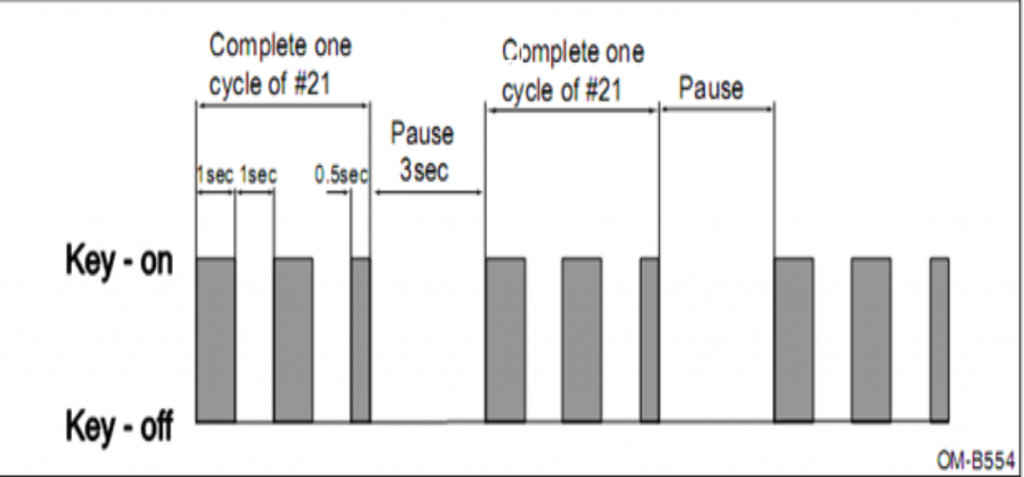

The examples below show how the malfunctions codes are displayedUsing the engine indicator light.

a. When the engine diagnostics button is turned on, watch the control lamp Engine.

b. The engine control lamp blinks, displaying the first digit of the fault code, then pausing, and then flashing again, showing the second digit Fault Code. For example, if the fault code is “21”, the flashes engine indicator lamp is twice (the first Qi”2″), then pause-1 sec, then flashes again (second digit “1”). The loop repeats to show the fault code more clearly.

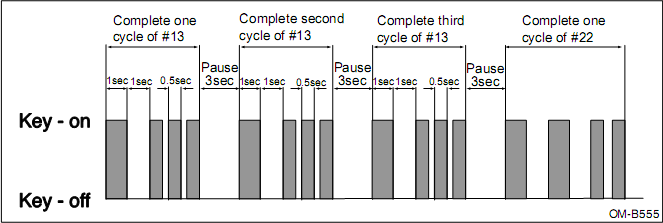

c. If you want to display two fault codes or more, the first code is displayed 3 times, the following code starts displayAzhatsja after 3 seconds pause. As indicated above, each fault code is repeated 3 times.

Example: one fault code 21

Example of displaying two fault codes 13 and 22

d. The following is an example of displaying fault codes in case of faults № 13 and № 22 were found simultaneously.

─ The engine is muted and the ignition key is in position ON

─ The lamp blinks once, then after 1 second blinks 3 times, and the whole sequence is repeated 3 times: fault code display 13 Completed.

─ The lamp blinks twice, then after 1 sec. Flashes Twice, and the whole sequence is repeated 3 times: The fault code display 22 is complete.

─ After the end of one cycle, you should pause Three seconds.

─ The fault code is repeated until the process is completed Check.

Removing the fault code

ToThe faults stored in the memory of the Electronic Control Module (ESM) can be easily removed from the Using the scanner.

The history of the eliminated fault codes is automatically removed from the ECU memory after 5 days.

Erasing the eliminated fault codes from the ECU memory can be done manually, turning on and off the ignition 5 times. Do not use this method permanently because it will affect the search time The service center using the scanner. NNeed will reproduce conditions of malfunctions in real conditions Engine operation when the vehicle is moving.

Table of fault codes for Daewoo Novus Ultra

| Fault Code | Fault content | Status | Conditions of Occurrence |

| 1.1 | No signal from temperature sensor

Coolant |

С | Faulty sensor/wiring

Coolant temperature too high |

| 1.2 | No signal from fuel temperature sensor | С | Faulty sensor/wiring the fuel temperature is too high |

| 1.3 | No signal from temperature sensor

Charge Air |

С | Inlet air temperature IntercoolerAbnormally

High. Defective engine/turbocharger/ Intercooler |

|

1.4 |

No signal from pressure sensor Charge Air |

С |

Faulty sensor/wiring

Inlet pressure, after Intercooler, abnormally high defective engine/turbocharger/ Intercooler |

| 1.6 | No signal from atmospheric air pressure sensor | С | Atmospheric pressure sensor attached to the ECU is defective |

| 1.7 | No signal from oil temperature sensor | N | Faulty sensor/wiring the oil temperature is too high |

| 1.8 | No signal from oil pressure sensor | С | Faulty sensor/wiring

Oil pressure too low (leakage, etc.) |

| 2.1 | Incorrect battery voltage

Battery |

С | Battery/generator/ECU Faulty |

| 2.2 | No signal from fuel pressure sensor | В | Faulty sensor/wiring |

| 2.3 | No signal from the electronic accelerator pedal | В | Faulty sensor/wiring/accelerator pedal switch |

|

2.4 |

No signal from the electronic accelerator pedal |

В |

Foot brake and accelerator pedal are used simultaneously while driving

Faulty sensor/switch/foot brake wiring |

| 2.5 | Faulty car speed sensor and tachometer | С | Faulty sensor/car tachometer/wiring |

| Fault code | Fault content | Status | Conditions of Occurrence |

| 2.7 | No signal from the clutch pedal sensor | С | Faulty sensor/wiring clutch pedal |

| 2.8 | No signal from the brake pedal sensor | С | Faulty sensor/wiring harness brake pedal |

| 2.9 | No signal from Cruise control switch | С | Faulty switch/wiring harness |

| 3.2 | The pressure in the fuel ramp is abnormally

Large deviations |

В | The pressure in the fuel ramp outside the permissible |

| 3.6 | Incorrect input signal value when

Operating system ASR |

N | ASR plug/wiring Harness Faulty |

| 3.7 | Non-standard signal on CAN bus system ASR and automatic transmission | N | ASR plug/wiring harness and automatic transmission faulty |

| 3.8 | Warning that the speed of rotation

Engine is excessively high |

С | Exceeding the maximum permissible engine speed

(Engine operation in different) |

|

3.9 |

Internal ECU relay malfunction (ECU block protection) |

В |

Operation of the ECU protection due to the short circuit in the wiring/sensors. As a rule, there is also another fault code (pedal sensors and Etc)

The internal protective relay ECU is malfunctioning. Failure to supply electricity |

| 4.1 | Emergency stopEngine | В | Motor Emergency Stop |

| 4.2 | No signal from crankshaft speed sensor | С | SENSOR/socket/wiring harness faulty sensor gap |

| 4.3 | No signal from camshaft speed sensor | С | Sensor/connector/harness wiring Faulty

Incorrect sensor clearance |

| 4.4 | Engine speed sensor faulty | С | The discrepancy between the signal values of crankshaft sensors and

Camshaft |

| 4.5 | The data storage unit in the ECU memory is faulty | С | The error occurs while storing important technical data in the ECU memory, when the engine is switched off |

| 4.6 | Does not start after the power supply is

ECU |

С | Emergency initialization of ECU unit |

|

4.7 |

The pressure limit valve in the fuel ramp opens abnormally high

Main pressure |

В |

The pressure limit valve is opened by force at an abnormally high main pressure greater than the pressure of the high pressure pump |

| 4.8 | Faulty power source | N | Battery voltage incorrect: ECU, battery or generator faulty |

| Fault Code | Fault content | Status | Conditions of Occurrence |

| 4.9 | The voltage on the injector (№ 1, 5, 3) deviates from the required value | В |

Cable/Injector connector faulty or defective ECU |

| 5.1 | The voltage on the injector (№ 6, 2, 4) deviates from the required value | В | |

| 5.8 | Contact with № 1 injector connector is broken | В |

Cable/Injector Connector Faulty |

| 5.9 | Contact with the № 5 injector connector is broken | В | |

| 6.1 | Contact with the № 3 injector connector is broken | В | |

| 6.2 | Contact with the № 6 injector connector is broken | В | |

| 6.3 | Contact with the № 2 injector connector is broken | В | |

| 6.4 | Contact with the № 4 injector connector is broken | В | |

| 6.6 | contact with the control lamp of the Glow candle

Faulty |

N | Lamp/connector/wiring Harness Faulty |

| 7.1 | Contact with faulty diagnostic lamp | N | Lamp/connector/wiring Harness Faulty |

| 7.2 | The relay of the candle is malfunctioning | С | Relay/connector/wiring harness malfunction |

| 7.3 | Relay № 2 Auxiliary engine brake is malfunctioning | N | Solenoid/connector/wiring Harness Faulty |

| 7.5 | Relay № 1 Auxiliary engine brake

invalid |

N | Solenoid/connector/wiring Harness Faulty |

| 8.3 | Contact with the fuel pump control valve is broken | С | Fuel pump control valve/wiring harness Faulty |

| 8.6 | Car engine speed meter does not work | N | Tachometer Motor/Harness wiring Faulty |

| 9.1 | Abnormal launch | В | The startup procedure is incorrect. Faulty ECU, power failure |

| Fault Code | Fault content | Status | Conditions of Occurrence |

| 9.2 | Low-quality ignition in the cylinder № 1 | С |

Faulty injector, low compression pressure, Faulty camshaft/crankshaft speed sensor signal |

| 9.3 | Low-quality ignition in the cylinder № 5 | С | |

| 9.4 | Low-quality ignition in the cylinder № 3 | С | |

| 9.5 | Low-quality ignition in the cylinder № 6 | С | |

| 9.6 | Low-quality ignition in the cylinder № 2 | С | |

| 9.7 | Low-quality ignition in the cylinder № 4 | С | |

| 9.8 | Low-quality ignition in multiple cylinders | С | |

| 9.9 | Injector Open Too long | С | Injector operation time exceeds standard values |

| 10.1 | Engine speed abnormally high (optional function) | С | The error occurs when calculating the engine speed with

Using the camshaft/crankshaft speed sensor |

| 10.2 | Contact with electronic accelerator pedal

Wrong |

В | The foot brake and the accelerator pedal work simultaneously,

When the car starts |

| 10.3 | Malfunctioning Cooling Fan | С | Faulty sensor/connector/wiring Harness |

| 10.4 | Fuel pressure is wrong | В | Large fluctuations of fuel pressure in the fuel ramp |

| 11.1 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.2 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.3 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.4 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.5 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.6 | Smooth operation of the engine

Non |

N | Excessive injector solenoid Core deviation |

* Status of malfunction

N: No Disruption of engine performance and performance.

С: Requires Check after work (no need for emergency check).

В: Requires Check and take action after working at low speed during the event.

DOOSAN Euro 4.5 (DL06 / DL08 / DV11). Daewoo Novus Truck Fault Codes DTC.

# — ERROR CODE (SPN) — FLASH CODE — FAULT DAEWOO NOVUS

1 — 18 — 2.2 — fuel pressure sensor

2 — 91 — 2.3 — accelerator pedal (APP1)

3 — 100 — 1.8 — oil pressure sensor

4 — 102 — 1.4 — intake air sensor

5 — 110 — 1.1 — coolant temperature sensor

6 — 132 — 2.6 — air flow sensor

7 — 158 — 2.1 — VOLT battery

8 — 171 — 1.5 — air temperature sensor

9 — 174 — 1.2 — fuel temperature sensor

10 — 175 — 1.7 — oil temperature sensor

11 — 190 — 4.4 — engine speed sensor (speed

12 — 597 — 2.8 — service brake switch

13 — 598 — 2.7 — clutch switch

14 — 602 — 2.9 — Cruise control

15 — 606 — 3.8 — engine revolutions

16 — 623 — 8.6 — low voltage power supply over 20

17 — 627 — 4.8 — power supply

18 — 647 — 7.2 — low voltage power supply over 7

19 — 723 — 10.6 — overspeed

20 — 734 — 5.8 — Solenoid. Power supply 1 or more

21 — 735 — 5.9 — Solenoid. Power supply 2 or more

22 — 736 — 6.1 — Solenoid. Power supply 3 or more

23 — 737 — 6.2 — Solenoid. Power supply 4 or more

24 — 738 — 6.3 — Solenoid. Power Supply 5 or more

25 — 739 — 6.4 — Solenoid. Power supply 6 or more

26 — 974 — 9.6 — remote choke

27 — 975 — 3.1 — MWIS module

28 — 977 — 11.6 — timeout message EMU1

29 — 1072 — 7.7 — undervoltage of the power supply unit over 12

30 — 1073 — 7.9 — undervoltage of the power supply unit over 14

31 — 1208 — 3.3 — regulation of the air pressure

32 — 1209 — 3.4 — exhaust control

33 — 1213 — 7.5 — undervoltage of the power supply unit more than 10

34 — 1238 — 3.6 — Auto T / M control

35 — 1320 — 1.6 — air pressure sensor

36 — 1322 — 10.4 — defective ignition in different cylinders

37 — 1323 — 9.7 — defective ignition cylinder # 1

38 — 1324 — 9.8 — defective ignition cylinder # 2

39 — 1325 — 9.9 — defective ignition cylinder # 3

40 — 1326 — 10.1 — defective cylinder # 4

41 — 1327 — 10.2 — defective ignition cylinder # 5

42 — 1328 — 10.3 — defective ignition cylinder # 6

43 — 1482 — 3.5 — T / M control

44 — 1485 — 3.9 — SCG main relay

45 — 1624 — 2.5 — machine speed

46 — 1639 — 11.5 — fan speed sensor

47 — 520193 — 1.3 — intake air temperature sensor

48 — 520194 — 1.9 — multiple position switch

49 — 520195 — 2.4 — gas pedal (APP2)

50 — 520196 — 3.2 — MPROP fuel pressure control

51 — 520196 — 11.7 — MPROPHIGH fuel pressure control

52 — 520197 — 3.7 — CAN-B Line

53 — 520198 — 4.1 — increased channel shut-off

54 — 520199 — 4.2 — engine speed sensor (crankshaft)

55 — 520 200 — 4 3 — Engine speed sensor

56 — 520201 — 4.5 — EEPROM data storage error in the electronic control unit

57 — 520202 — 4.6 — activation error after switching on the electronic control unit

58 — 520203 — 4.7 — PRV check error

59 — 520 204 — 4.9 — SCB main relay failure

60 — 520205 — 5.1 — ECM main relay failure

61 — 520206 — 9.1 — CAN-ALine

62 — 520207 — 5.2 — cylinder balance, cylinder 1

63 — 520256 — 5.3 — cylinder balance, cylinder 2

64 — 520257 — 5.4 — cylinder balance, cylinder 3

65 — 520258 — 5.5 — cylinder balance, cylinder 4

66 — 520259 — 5.6 — cylinder balance, cylinder 5

67 — 520260 — 5.7 — cylinder balance, cylinder 6

68 — 520262 — 6.6 — undervoltage of the power supply unit more than 2

69 — 520262 — 8.3 — undervoltage of the power supply unit over 17

70 — 520263 — 6.7 — undervoltage of unit 3

71 — 520264 — 7.3 — undervoltage of the power supply unit over 8

72 — 520265 — 7.4 — undervoltage of the power supply unit over 9

73 — 520266 — 7.8 — undervoltage of the power supply unit over 13

74 — 520267 — 7.6 — undervoltage of the power supply unit over 11

75 — 520268 — 6.9 — undervoltage of the power supply unit over 5

76 — 520269 — 6.8 — undervoltage of the power supply unit more than 4

77 — 520270 — 8.1 — undervoltage of the power supply unit over 15

78 — 520271 — 8.2 — undervoltage of the power supply unit over 16

79 — 520272 — 8.4 — undervoltage of the power supply unit over 18

80 — 520273 — 8.5 — undervoltage of the power supply unit over 19

81 — 520274 — 8.7 — undervoltage of the power supply unit over 21

82 — 520275 — 8.8 — undervoltage of the power supply unit over 22

83 — 520276 — 8.9 — undervoltage of the power supply unit over 23

84 — 520277 — 9.2 — undervoltage of the power supply unit over 24

85 — 520278 — 9.3 — undervoltage of the power supply unit over 25

86 — 520320 — 9.4 — undervoltage of the power supply unit over 26

87 — 520324 — 6.5 — undervoltage of the power supply unit more than 1

88 — 520325 — 7.1 — undervoltage of the power supply unit more than 6

89 — 520326 — 10.5 — injector was opened too long

90 — 520327 — 10.7 — accelerator pedal (ARRZ)

91 — 520328 — 10.8 — Continuous ignition control Seg-0

92 — 520329 — 10.9 — Continuous ignition control Seg-1

93 — 520330 — 11.1 — Continuous ignition control Seg-2

94 — 520331 — 11.2 — Continuous ignition control Seg-3

95 — 520332 — 11.3 — Continuous ignition control Seg-4

96 — 520333 — 11.4 — Continuous ignition control Seg-5

97 — 520334 — 11.7 — inlet air pressure plausibility

98 — 520335 — 11.8 — inlet air temperature plausibility

99 — 520336 — 11.9 — coolant temperature plausibility

100 — 520337 — 12.1 — oil temperature plausibility

101 — 520338 — 12.2 — fuel pressure plausibility

102 — 520339 — 12.3 — UDV protection — lowest “torque” value

103 — 520340 — 12.4 — UDV protection — highest “torque” value

104 — 520341 — 12.5 — DCU

DIAGNOSTICS OF ENGINES DL06, DL08, DV11

Diagnosis of the engine can be carried out using a diagnostic scanner or by checking the DTCs displayed on the instrument panel by a flashing warning light with

engine image.

We recommend using a diagnostic scanner as it provides a quick and accurate check.

Diagnostic procedure

a) Turn the main battery switch to the «ON» position.

b) The ignition key is in the «ON» position.

c) The engine is not running.

d) Press the engine diagnostics button. (Hold for 2 sec).

e) The control lamp with the engine image will start blinking on the instrument panel.

f) Check the trouble codes, then turn the ignition key to the «OFF» position.

Fault code display

The examples below show how fault codes are displayed with

using the engine indicator light

Clearing a fault code

DTCs stored in the electronic control module (ECM) memory can be easily erased using a scanner.

The history of the corrected codes of malfunctions is deleted automatically from the ECU memory after 5 days.

Clearing the corrected fault codes from the ECU memory can be done manually by turning the ignition on and off 5 times. Do not use this method all the time, as this will affect the search time

service center using a scanner. It will be necessary to reproduce the conditions for the occurrence of malfunctions in the real conditions of engine operation when the vehicle is moving.

NO . ERROR CODE ( SPN ) FLASH CODE FAULT DAEWOO NOVUS

1 18 2.2 fuel pressure sensor

2 91 2.3 gas pedal (APP1)

3 100 1.8 oil pressure sensor

4 102 1.4 intake air sensor

5 110 1.1 coolant temperature sensor

6 132 2.6 air flow sensor

7 158 2.1 battery VOLT

8 171 1.5 air temperature sensor

9 174 1.2 fuel temperature sensor

10 175 1.7 oil temperature sensor

11 190 4.4 engine speed sensor (speed

12 597 2.8 service brake switch

13 598 2.7 clutch switch

14 602 2.9 Cruise Control

15 606 3.8 engine speed

16 623 8.6 low voltage of the power supply more than 20

17 627 4.8 power supply

18 647 7.2 low voltage of the power supply more than 7

19 723 10.6 engine overspeed

20 734 5.8 Solenoid. Power supply 1 or more

21 735 5.9 Solenoid. Power supply unit 2 or more

22 736 6.1 Solenoid. Power supply 3 or more

23 737 6.2 Solenoid. Power supply 4 or more

24 738 6.3 Solenoid. Power supply 5 or more

25 739 6.4 Solenoid. Power supply unit 6 or more

26 974 9.6 remote throttle

27 975 3.1 MWIS module

28 977 11.6 EBC1 message timeout

29 1072 7.7 under voltage of the power supply more than 12

30 1073 7.9 under voltage of the power supply more than 14

31 1208 3.3 Inlet air pressure control

32 1209 3.4 exhaust gas regulation

33 1213 7.5 under voltage of the power supply unit more than 10

34 1238 3.6 Auto T / M control

35 1320 1.6 air pressure sensor

36 1322 10.4 ignition defects in different cylinders

37 1323 9.7 defective ignition cylinder # 1

38 1324 9.8 defective ignition cylinder # 2

39 1325 9.9 defective ignition cylinder # 3

40 1326 10.1 defective ignition cylinder # 4

41 1327 10.2 defective ignition cylinder # 5

42 1328 10.3 defective ignition cylinder # 6

43 1482 3.5 T / M control

44 1485 3.9 main relay SCG

45 1624 2.5 machine speed

46 1639 11.5 fan speed sensor

47 520193 1.3 intake air temperature sensor

48 520194 1.9 Multiple position switch

49 520195 2.4 gas pedal (APP2)

50 520196 3.2 MPROP fuel pressure control

51 520196 11.7 MPROPHIGH fuel pressure control

52 520197 3.7 CAN — In Line

53 520198 4.1 increased channel shut — off (shutdown)

54 520199 4.2 engine speed sensor ( crankshaft)

55 520200 4 3 Engine speed sensor

56 520201 4.5 EEPROM data storage error in the electronic control unit

57 520202 4.6 activation error after turning on the electronic control

unit

58 520203 4.7 PRV check

error

59 520204 4.9 malfunction of the main

relay SCB

60 520205 5.1 malfunction of the main relay

ECM

61 520206 9.1 CAN — ALine

62 520207 5.2 balance cylinder, cylinder

1

63 520256 5.3 balance cylinder, cylinder 2

64 520257 5.4 cylinder balance, cylinder

3

65 520258 5.5 cylinder balance, cylinder

4

66 520259 5.6 cylinder balance, cylinder

5

67 520260 5.7 balance cylinder, cylinder

6

68 520262 6.6 undervoltage of the power supply more than

2

69 520262 8.3 undervoltage of the power supply over

17

70 520263 6.7 undervoltage of unit

3

71 520264 7.3 undervoltage of the power supply more than

8

72 520265 7.4 undervoltage of the power supply more than

9

73 520266 7.8 undervoltage of the power supply unit more than

13

74 520267 7.6 undervoltage of the power supply more than

11

75 520268 6.9 undervoltage of the power supply more than

5

76 520269 6.8 undervoltage of the power supply more than

4

77 520270 8.1 undervoltage of the power supply unit more than

15

78 520271 8.2 undervoltage of the power supply unit more than

16

79 520272 8.4 undervoltage of the power supply more than

18

80 520273 8.5 undervoltage of the power supply more than

19

81 520274 8.7 undervoltage of the power supply more than

21

82 520275 8.8 undervoltage of the power supply unit more than

22

83 520276 8.9 undervoltage of the power supply over

23

84 520277 9.2 undervoltage of the power supply more than

24

85 520278 9.3 undervoltage of the power supply unit more than

25

86 520320 9.4 undervoltage of the power supply more than

26

87 520324 6.5 undervoltage of the power supply unit more than

1

88 520325 7.1 undervoltage of the power supply unit more than

6

89 520326 10.5 the injector was opened too

long

90 520327 10.7 gas pedal

(ARRZ)

91 520328 10.8 control of smooth

ignition Seg -0

92 520329 10.9 control of smooth

ignition Seg -1

93 520330 11.1 Smooth ignition

control Seg -2

94 520331 11.2 control of smooth

ignition Seg -3

95 520332 11.3 Smooth ignition

control Seg -4

96 520333 11.4 control of smooth

ignition Seg -5

97 520334 11.7 intake air

pressure plausibility

98 520335 11.8 intake air

temperature plausibility

99 520336 11.9 coolant

temperature plausibility

100 520337 12.1 oil

temperature plausibility

101 520338 12.2 fuel

pressure plausibility

102 520339 12.3 UDV protection — lowest value of

«torque»

103 520340 12.4 UDV protection — the highest value of

«torque»

104 520341 12.5 DCU

* DDC Engine

1. How to read engine diagnostic codes

Code 13(SEL Active codes)

⇔

SEL

1 Flash

The active code will be flashed on the SEL(code «25» if there is no malfunction code). Then the inactive

code will be flashed on the CEL(code «25» if there is no malfunction code).

The process of flashing all the inactive codes will repeat until the conditions for code flashing are no longer

satisfied.

Codes

VSG sensor input voltage low

11

VSG sensor input voltage high

12

Coolant level sensor input voltage low

13

Oil, coolant, or intercooler, temp. sensor input voltage high

14

Oil, coolant, or intercooler, temp. sensor input voltage low

15

Coolant level sensor input voltage high

16

Bypass or throttle, valve position sensor input voltage

17

high Bypass or throttle, valve position sensor input

18

voltage low

21

TPS input voltage high TPS input voltage low

22

Fuel temp. sensor input voltage high Fuel

23

temp. sensor input voltage low

24

No active codes

25

Aux. engine shutdown #1, or #2, input active

26

Air inlet or intake air, temp. sensor input voltage high

27

Air inlet or intake air, temp. sensor input voltage low

28

Aux. high side output open circuit or short to ground

31

CEL or SEL short to battery(+) or open circuit

32

Turbo boost sensor input voltage high Turbo

33

boost sensor input voltage low Oil pressure

34

sensor input voltage high Oil pressure sensor

35

input voltage low

36

Fuel pressure sensor input voltage high Fuel

37

pressure sensor input voltage low

38

Too may SRS (missing TRS) Too few SRS(missing

41

SRS)

42

Coolant level low

43

Oil, coolant, intercooler or intake air, temp. high

44

Oil pressure low

45

ECM battery voltage low

46

Fuel, air inlet, or turbo boost, pressure high

47

https://www.truck-manuals.net/

SEL

SEL

SEL

3 Flashes

Description

1-31 HOW TO HANDLE THE VEHICLE

Code 21(CEL Inactive codes)

⇔

CEL

2 Flashes

Codes

48 Fuel or air inlet pressure low

52 ECM A/D conversion fault

53 ECM non volatile memory fault

54 Vehicle speed sensor fault

55 J1939 data link fault 56 J1587 data link fault 57

J1922 data link fault

58 Torque overload

61 Injector response time long

62 Aux. output short to battery(+) or open circuit, or mech. fault

63 PWM drive short to battery(+) or open circuit.

64 Turbo speed sensor input fault

65 Throttle valve position input fault 66 Engine knock

sensor input fault

67 Coolant or air inlet, pressure sensor input voltage fault

68 TPS idle validation switch open circuit or short to ground

71 Injector response time short

72 vehicle overspeed

73 Gas valve position input fault or ESS fault 74

Optimized idle safety loop short to ground

75 ECM battery voltage high

76 Engine overspeed with engine brake

77 Fuel temperature high

81 Oil level, crankcase prs, dual fuel BOI, or exh. temp. volt high

82 Oil level, crankcase prs, dual fuel BOI, or exh. temp. volt low

83 Oil level, crankcase prs, exhaust temp.,or external pump

prs.,high

84 Oil level or crankcase pressure, low

85 Engine overspeed

86 External pump or barometer, pressure sensor input voltage high

87 External pump or barometer, pressure sensor input voltage low

88 Coolant pressure low

⇔

CEL

CEL

1 Flash

Description