|

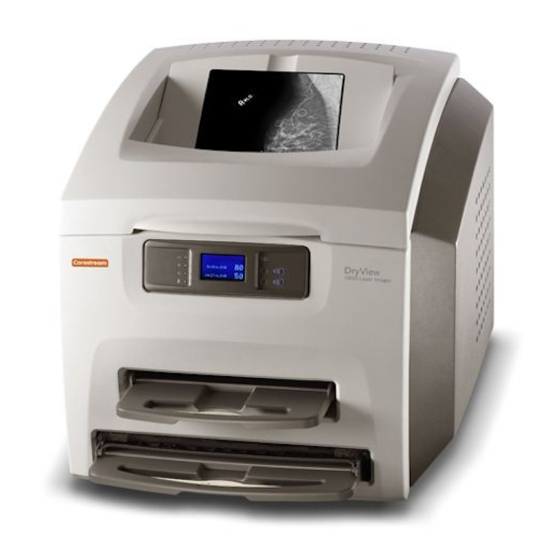

kodak dryveiw 5800 |

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

Troubleshooting

Code

01004

MIM Core: Internal Software

Error

04200

MIM Core: Disk Full

06400

MIM Core: Image Page Error

06410

MIM Core: Image Rendering

Error

06411

MIM Core: Image Data Error

06420

MIM Core: Internal Software

Error

06430

MIM Core: Internal Software

Error

10001

MIS: Internal Software Error

3-6

Condition codes are shown on the display screen in the order in which they

are generated. If there is more than one code associated with the current

condition of the imager, the first code is shown on the display screen for six

seconds, while other codes in the list are displayed for three seconds as the

list is cycled. The LEDs on the left side of the local panel will be on

whenever there is a condition code of that type.

Table 3-5: Condition Codes

Web Portal Message

User Action

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Delete jobs in the «Unprintable jobs» queue.

2. Load requested film type for jobs in the «Waiting

for media» queue.

3. If the error persists, call for service.

1. Delete jobs in the «Unprintable jobs» queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Delete jobs in the «Unprintable jobs» queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Delete jobs in the «Unprintable jobs» queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Delete jobs in the «Unprintable jobs» queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Delete jobs in the «Unprintable jobs» queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

2G0733

2011-09-09

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

KODAK DRYVIEW 5800 Laser Imager

CARESTREAM DRYVIEW 5850 Laser Imager

User’s Guide

Related Manuals for Kodak Dryview 5800

Summary of Contents for Kodak Dryview 5800

-

Page 1

KODAK DRYVIEW 5800 Laser Imager CARESTREAM DRYVIEW 5850 Laser Imager User’s Guide… -

Page 3: Table Of Contents

DRYVIEW 5800 and 5850 Laser Imagers — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — -…

-

Page 4

Table of Contents Clearing Film Jams — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 3-13 Film Jam — Code 2x-116 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 3-14 Film Jam — Code 2×126 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 3-17 Film Jam — Code 26325 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 3-19… -

Page 5: Overview

Chapter 5 of this manual. Intended Use The KODAK DRYVIEW 5800 Laser Imager provides high quality hard copy film output from digital imaging source modalities for use in medical imaging diagnosis and referral. Electronic image information signals are managed and transformed optically to expose KODAK DRYVIEW media.

-

Page 6: How The Laser Imager Works

Overview How the Laser Imager Works The imager is a network printer connected on a network along with one or more medical imaging devices. It prints images sent over the network from medical imaging devices or workstations sending images concurrently. Modality Network Modality…

-

Page 7: System Components

Overview System Components Film trays. Your imager is configured with two film trays. Each film tray holds a different size of film. Both film trays must be installed in order for the imager to operate. Film feed transport. The film feed transport orients and centers the film while moving the film from the film tray to the imaging portion of the imager.

-

Page 8: Print Sequence

Overview Print Sequence When the imager receives a print request, it determines the requested film size and type and then it selects the appropriate film tray. Each time the imager receives a print request, the following print sequence occurs: 1. Suction cups in the pickup area lift a single sheet of film out of the tray and feed the film into the transport rollers.

-

Page 9: Automatic Image Quality Control

Overview Automatic Image Quality Control An internal densitometer is a key element in the Automatic Image Quality Control (AIQC) process. The densitometer enables the imager to automatically adjust image processing parameters to produce the best image. The imager adjusts these parameters each time it prints a calibration film. A calibration film is printed when: •…

-

Page 11: Using And Maintaining The Imager

Using and Maintaining the Imager Operator Control of the Imager During normal operation, the imager receives and automatically prints images sent by modalities over a network. Very little operator control is required. The main responsibilities of the operator are described in the following section, along with overview information about using the imager.

-

Page 12: Local Panel And Display Screen

Using and Maintaining the Imager Local Panel and Display Screen Local Panel / Display Screen Ready LED. When steady on, the LED indicates that the imager is ready for printing. When flashing, the imager is processing and printing films. When unlit, the imager is not ready to print.

-

Page 13: Display Screen Icons

Using and Maintaining the Imager Display Screen Icons Icon Description This icon indicates that film calibration is required. The imager is unable to print jobs from this tray until a successful calibration occurs. This icon indicates that a door is open on the imager. This icon indicates an error with the film tray.

-

Page 14

Using and Maintaining the Imager Icon Description Icons in Menu Selection Mode The following icons appear on the display screen when you are in Menu Selection Mode. These icons represent the changed functionality of the buttons on the right side of the local panel. While in Menu Selection Mode, press the button (6 in the graphic on page 2-2) to display the Test Print or Maintenance Reset screen. -

Page 15: Web Portal

Using and Maintaining the Imager Web Portal The Web Portal is your interface to additional functions on the imager. In the Web Portal, you can view and manage the imager’s connections over the network, configure features, and view and correct error messages and general status.

-

Page 16: Accessing The Web Portal

Using and Maintaining the Imager Accessing the Web To access the Web Portal, you will need a desktop or laptop computer that is Portal connected to the network. 1. On a desktop or laptop computer, start MICROSOFT INTERNET EXPLORER. 2. In the address field, type: http://<IP address> NOTE: <IP address>…

-

Page 17: Operations

Using and Maintaining the Imager Operations Unloading and IMPORTANT: Leave the imager powered on while loading or unloading loading the Film Tray the film tray. When 100 sheets of film have been used, a 0 film count appears on the display screen.

-

Page 18

Using and Maintaining the Imager Bag holder Film package Diverter 4. Pull the diverter (plastic bar) and bag holder (silver bar) into the up position. 5. Press the new film package down in the tray with the label facing up. 6. -

Page 19

Using and Maintaining the Imager Tear strip 10. Remove the tear strip from the plastic bag. 11. Swing the diverter of the film tray back in place. IMPORTANT: Do not install the film saver onto the film tray. 12. Slide the tray back into the imager slot. Plastic bag 13. -

Page 20: Inserting The Film Saver And Removing The Film Tray

Using and Maintaining the Imager Inserting the Film A film saver must be inserted into a film tray before: Saver and Removing • The hood is opened. the Film Tray • Any panel on the imager is removed. • Film tray with film in it is removed. 1.

-

Page 21: Calibration Prints

Using and Maintaining the Imager Calibration Prints imager calibration is performed by printing a calibration print. A calibration print has a step wedge pattern with a series of 26 stripes of increasing optical density. The only purpose of a calibration print is to calibrate the imager.

-

Page 22: Working With Quality Test Prints

Using and Maintaining the Imager Working with Quality The imager can print an internally generated density test print with a Test Prints SMPTE pattern. Density test prints can be used as a quality assurance tool to verify the uniformity of films printed by the imager. The 5850 Laser Imager provides additional test images that can be used for mammography quality control.

-

Page 23: Operator Maintenance

Using and Maintaining the Imager Operator Maintenance Changing the Charcoal Filter CAUTION In the U.S., exhausted charcoal filters are considered to be non-hazardous waste according to the U.S. Environmental Protection Agency Resource Conservation Recovery Act (RCRA). Municipality owned and licensed solid waste management facilities are an appropriate disposal option.

-

Page 24

Using and Maintaining the Imager 3. Raise the hood. 4. Pull the front panel forward. 5. Remove the charcoal filter by lifting it up and pulling it forward. 6. Install a new charcoal filter. 7. Close the front panel. 8. Close the hood. 9. -

Page 25: Troubleshooting

Troubleshooting Error and Alarm Indications The imager can detect errors and other conditions that require operator action. These errors or abnormal conditions are reported on the display screen and on the Web Portal in the form of condition codes and messages.

-

Page 26: Printer Status Messages

Troubleshooting Printer Status Messages The following table describes how the local panel and Web Portal indicate printer status to the user. Table 3-2: Printer Status Messages Printer Web Portal Local Panel DICOM Status Description Status Display Any Film • Ready LED off Not Ready WARNING / At least one of the film…

-

Page 27: Film Tray Status Messages

Troubleshooting Table 3-2: Printer Status Messages (Continued) Printer Web Portal Local Panel DICOM Status Description Status Display Warming • Ready LED off Warming=xx WARNING / The Processor is warming • Warming LED on PROC INIT up and will not be ready to •…

-

Page 28

Troubleshooting Table 3-3: Film Tray Status Messages (Continued) Film Tray Web Portal Local Panel Description State Display Manual Mode • Attention LED on The film in this film tray does • Status code: 21002 (upper), not meet AIQC standards. 23002 (lower) However, the user has selected •… -

Page 29: Job Manager Status Messages

Troubleshooting Job Manager Status Messages The following table describes how the local panel and Web Portal indicate job status to the user. Table 3-4: Job Manager Status Messages Job Manager Web Portal Display Screen Description Status Display Active Shows how many The imager is accepting DICOM job jobs having this requests and film is available for all current…

-

Page 30: Condition Codes

Troubleshooting Condition Codes Condition codes are shown on the display screen in the order in which they are generated. If there is more than one code associated with the current condition of the imager, the first code is shown on the display screen for six seconds, while other codes in the list are displayed for three seconds as the list is cycled.

-

Page 31

Troubleshooting Table 3-5: Condition Codes (Continued) Code Web Portal Message User Action 10003 MIS: Image Buffer Error 1. Shut down the imager, then start the imager. 2. If the error persists, call for service. 10015 MIS: Database Error 1. Shut down the imager, then start the imager. 2. -

Page 32

Troubleshooting Table 3-5: Condition Codes (Continued) Code Web Portal Message User Action 20703 none 1. Press and hold the Menu Selection button for five seconds. 2. Press and release the Menu Selection button again to display the Error Reset menu. Delete the jobs in the Unprintable Jobs Queue. -

Page 33

Troubleshooting Table 3-5: Condition Codes (Continued) Code Web Portal Message User Action 21119 or xxxxx Supply: Internal 1. Cover the film tray with the film saver. Remove the 23119 Hardware Failure tray from the imager. 2. Re-insert the film tray and remove the film saver. 3. -

Page 34

Troubleshooting Table 3-5: Condition Codes (Continued) Code Web Portal Message User Action 21146 or xxxxx Supply: Unsupported 1. The imager has not been configured to use this film 23146 Film Size size. 2. Try a different film size or reconfigure the imager. 3. -

Page 35

Troubleshooting Table 3-5: Condition Codes (Continued) Code Web Portal Message User Action 27123 Optics: Internal Hardware 1. Shut down the imager, then start the imager. Failure 2. If the error persists, call for service. 27601 Optics: Calibration Failed 1. Shut down the imager, then start the imager. 2. -

Page 36

Troubleshooting Table 3-5: Condition Codes (Continued) Code Web Portal Message User Action 28931 Processor: Internal 1. Shut down the imager, then start the imager. Communications Failure 2. If the error persists, call for service. 29154 Densitometer: Internal 1. Shut down the imager, then start the imager. Communications Failure 2. -

Page 37: Clearing Film Jams

Troubleshooting Clearing Film Jams CAUTION Shutting off power to clear a film jam is not required. Jam Areas and Film Path 2011-09-09 2G0733 3-13…

-

Page 38: Film Jam — Code 2X-116

Troubleshooting Film Jam — Code 1. Remove the film trays (see “Inserting the Film Saver and Removing 2x-116 the Film Tray”). Film tray slots 2. Remove any misplaced films from Area 1. This area can be accessed through the film trays slots. NOTE: If the film is not accessible from the front of the imager, continue with…

-

Page 39

Troubleshooting Hood Left panel 2 thumb screws 3. Open the hood. 4. Loosen the 2 thumb screws and remove the left panel. 2011-09-09 2G0733 3-15… -

Page 40

Troubleshooting Pickup access areas 5. Remove any misplaced films seen in the pickup access areas. 6. If Area 1 did not contain misplaced films, take the film trays to a dark room and remove the film saver. Remove any misplaced films and cover the tray with the film saver. -

Page 41: Film Jam — Code 2X126

Troubleshooting Film Jam — Code 1. Remove the film trays (see “Inserting the Film Saver and Removing 2×126 the Film Tray”). Film tray slots 2. Remove any misplaced films from Area 1. This area can be accessed through the film trays slots. 3.

-

Page 42

Troubleshooting Hood Left panel 2 thumb screws 5. Open the hood. 6. Loosen the 2 thumb screws and remove the left panel. Pickup access areas 3-18 2G0733 2011-09-09… -

Page 43: Film Jam — Code 26325

Troubleshooting 7. Remove any misplaced films seen in the pickup access areas. 8. Set the left panel in place and tighten the 2 thumb screws. 9. Close the hood. Film Jam — Code IMPORTANT: If this error occurred at the same time as 2x-126, follow the 26325 instructions for “Film Jam — Code…

-

Page 44

Troubleshooting 4. Carefully remove any films found in the drum area. 5. Close the drum cover and secure the cover latches. If the film was not found in the drum area, continue with Step Hood Left panel 2 thumb screws 6. -

Page 45: Film Jam — Code 26544

Troubleshooting Film advance knob 8. Use the manual advance knob to move the film through the processor. 9. Set the left panel in place and tighten the 2 thumb screws. 10. Close the hood. If film was not previously removed, the misplaced films will emerge from the imager within two minutes.

-

Page 46: Calling For Support

Troubleshooting Calling for Support If you cannot correct a condition and need help, call for support. Have the following information ready when you call: • Model Number • Serial Number or K-Number • Condition code and message if they are shown on the display screen and Web Portal 3-22 2G0733…

-

Page 47: Film Technical Information

Film Technical Information General Description This section describes the characteristics of laser imaging film, not the operation of the laser imager. The laser imaging film is a high-resolution, infrared-sensitive, photothermographic film designed specifically for the laser imager. The laser imaging film is packaged in daylight-load packages and is available in blue, clear, and mammography film types.

-

Page 48: Environmental Impact

Film Technical Information Environmental Tests show that the laser imaging film is not considered hazardous to the Impact environment. As a result, you can develop, recycle, and dispose of film with less impact on the environment than if you were using wet-developed silver halide films.

-

Page 49: Archiving Developed Film

Film Technical Information lighting. This is virtually undetectable and has no effect on image quality (typically 0.02 change in density). This small density increase is uniform and permanent upon full exposure of the film under normal handling conditions (room light or view box). Archiving Developed The laser imaging film has been tested and can be archived for more than Film…

-

Page 51: Specifications

Specifications Location Equipment Specifications Unpacked Packed Height 62 cm (24 in.) 95 cm (37 in.) Width 62 cm (24 in.) 81 cm (32 in.) Depth 66 cm (26 in.) without film trays 106 cm (42 in.) 76 cm (30 in.) with film trays Weight 70 kg (155 lb) 147.4 kg (325.0 lb)

-

Page 52: Other Location Considerations

Specifications Other Location Additional factors that influence where the imager is located include Considerations proximity to patients, flammable materials, liquids, and other equipment. CAUTION This equipment is not contained in a sealed cabinet. Do not use this equipment in locations where it can come in contact with liquids, including body fluids.

-

Page 53: Environmental Requirements

Specifications Environmental Requirements Temperature • Operating: 15–33 °C (59–91 °F) • Storage: From –40 through 60 °C (From –40 through 140 °F) Relative Humidity • Operating: 20–80 % RH, noncondensing • Storage: 10–90 % RH, noncondensing Altitude 30 m (100 ft) below sea level to 2438 m (8000 ft) above sea level Surface Condition The surface must be a level (must be level within 1 °) table top or counter capable of supporting the weight of the imager.

-

Page 54: Power Requirements

KODAK DRYVIEW DVB+ Laser Imaging Film • KODAK DRYVIEW DVB+ Premium Laser Imaging Film • 5850 Laser Imager only: KODAK DRYVIEW Mammography Laser Imaging Film and KODAK DRYVIEW DVM+ Mammography Laser Imaging Film NOTE: Not all film types are available in every country. 2G0733…

-

Page 55: Film Sizes

Specifications Film Sizes The imager accommodates the following film sizes: • 20 x 25 cm (8 x 10 in.) • 25 x 30 cm (10 x 12 in.) • 28 x 35 cm (11 x 14 in.) • 35 x 35 cm (14 x 14 in.) •…

-

Page 57: Glossary

Glossary Computed Radiography, the process of creating digital radiographic images. Computed Tomography, the process of creating digital tomographic images. Cycle power Cycle power means to shut down and power up the Laser Imager. DICOM Digital Imaging and Communications in Medicine. A TCP/IP-based protocol for transmitting and receiving medical imaging and related data over a network.

-

Page 58

Glossary Test type The type of test film that will be printed. Two film test types are available: a density test film (SMPTE pattern) and a calibration film. Transfer Function Tables. Unprintable queue The queue of jobs that cannot be printed because of problems with the job description. -

Page 59

Index Agency compliance, 1-5 Job manager status messages, 3-5 Altitude, 5-3 Automatic image quality control (AIQC), 1-5 Laser specifications, 5-3 Local panel layout, 2-2 Calling for support, 3-22 Conventions, 1-5 Correcting film jams, 3-13 MCS printer status messages, 3-2 Messages DICOM printer status, 3-1 DICOM, 1-1 Film supply status, 3-3… -

Page 61

Publication History Revision Date Reason for Change 2008-01-14 First release 2009-02-27 Incorporated details for 5850 Laser Imager. 2009-05-06 Updated the Intended Use statement for the 5850 Laser Imager 2011-09-09 Modified formatting of dates and measurements (EN 1041) -

Page 62

Carestream Health, Inc. 150 Verona Street Rochester, NY 14608 © Carestream Health, Inc., 2011 CARESTREAM and DRYVIEW are trademarks of Carestream Health, Inc. The Kodak trademark and trade dress are used under license from Kodak. Pub No. 2G0733 Rev. D…

Service manual for the Kodak 5800 Dryview film printer. The Dryview 5800 is a medical film printer capable of DICOM connections over a network.This manual covers detailed installation and maintenance as well as error code descriptions.

-

Carestream Health, 2008

Publication No. 2G094731JAN08

SERVICE MANUAL

for the

Kodak DryView 5800 LASER IMAGER

Service Code: 1115

IMPORTANT: Qualified service personnel must install and repair

this equipment. When doing the procedures in this document, you

must use safe work practices and wear the correct PersonalProtective Equipment (i.e., SAFETY EYEWEAR) according to your

Companys Standard Operating Procedures.Downloaded from www.Manualslib.com manuals search engine

-

PLEASE NOTE The information contained herein is based on the

experience and knowledge relating to the subject matter gained by

Carestream Health, Inc. prior to publication.No patent license is

granted by this information.Carestream Health, Inc. reserves the

right to change this information without notice, and makes no

warranty, express or implied, with respect to this information.

Carestream Health, Inc. shall not be liable for any loss or damage,

including consequential or special damages, resulting from any use

of this information, even if loss or damage is caused by Carestream

Health, Inc.s negligence or other fault.Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 iii

Table of ContentsSafety Information — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — 1-1Installation Instructions — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— 2-1Packing List — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — 2-1Necessary Materials — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— 2-1Connecting the LAPTOP COMPUTER to the IMAGER — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — 2-2Energizing the

IMAGER — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — 2-3De-energizing the

IMAGER — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — 2-3Logging Onto the SERVICE

TOOL — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — 2-4Logging Off the SERVICE TOOL — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — 2-4Doing the Mechanical Setup — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — 2-5Completing the Uncrating — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

2-5Checking the Accessories — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — 2-6Moving

the IMAGER — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — 2-7Removing the

SHIPPING RESTRAINTS and Packing Material — — — — — — — — — — — — —

— — — — — — — — — — 2-7Doing the Configuration — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

2-13Setting the Language — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

2-13Checking the Values for the DICOM Source Communications — — — —

— — — — — — — — — — — — — — — — — — — 2-13Setting the IMAGER to be

a Destination — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — 2-14Setting the System Clock — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — 2-16Setting the Host Name and the IP Address — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

2-19Setting up Service Tracking — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

2-20Loading Customer Film — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

2-21Checking the Installed Hardware and Film Type — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — 2-21Doing the SCP

Services Configuration — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — 2-22Checking Image Quality — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — 2-23Editing the Service History Log — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — 2-26Configuring the CARESTREAM REMOTE MANAGEMENT

SERVICES — — — — — — — — — — — — — — 2-27Backing Up the System

Configuration — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — 2-31Instructing the Operator — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — 2-32Using the Default Passcode — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — 2-32Adjustments and Replacements — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

3-1Adjustments — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— 3-1PROCESSOR — DRUM Temperature — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — 3-1IMAGING AY —

Alignment — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — 3-5IMAGING AY — Start Index

Delay, Start of Scan — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — 3-7IMAGING AY — Page Start Delay, Start of Page

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

3-9Replacements — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

3-12LEFT PANEL — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

3-12RIGHT PANEL — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — 3-13BACK

PANEL — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — 3-14TOP COVER — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — 3-15FRONT PANEL — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — 3-17LOCAL PANEL AY — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — 3-18SWITCH, INTERLOCK — LEFT and RIGHT PANELS — —

— — — — — — — — — — — — — — — — — — — — — — — — — — 3-19SWITCH,

INTERLOCK — TOP COVER — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — 3-21SWITCH, SERVICE — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — 3-22PROCESSOR AY — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — 3-23PROCESSOR DRUM — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

3-27Downloaded from www.Manualslib.com manuals search engine

-

iv 2G0947 — 31JAN08

PROCESSOR COVER — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — -3-29BELT, DRUM

DRIVE — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — -3-30MOTOR, DRUM DRIVE (M8) —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — -3-31FAN AY, PROCESSOR — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — -3-32FILM DIVERTER AY and FELT PAD AY — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — -3-33PROCESSOR GASKET

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — -3-35PROCESSOR ROLLERS — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — -3-37DENSITOMETER AY — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-38TURNAROUND DRIVE SHAFT, DRIVE WHEEL and HUBS — — — — — — — — —

— — — — — — — — — — — — — -3-41TURNAROUND IDLER SHAFTS and ROLLERS

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-45MOTOR, TURNAROUND ROLLER DRIVE (M9) — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — -3-47FILM FEED AY — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — -3-48MOTOR, FEED ROLLER NIP OPEN/CLOSE (M1)

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-53MOTOR, NIP POSITION DRIVE (M2) — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — -3-54FEED ROLLER NIP

DRIVE BELT — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — -3-55NIP ROLLER SET AY — UPPER — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — -3-57NIP ROLLER SET AY — LOWER — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — -3-58FILM

SEPARATION FAN AY — UPPER — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — -3-60FILM SEPARATION FAN AY — LOWER

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — -3-62FILM SEPARATION FAN FILTER — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — -3-63CAM AY,

CASSETTE REGISTRATION — UPPER (M6U) — — — — — — — — — — — — — — — —

— — — — — — — — — -3-64CAM, AY CASSETTE REGISTRATION — LOWER (M6L)

— — — — — — — — — — — — — — — — — — — — — — — — — -3-65SENSOR, FILM

SAVER DETECT — UPPER (S6U) — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — -3-66SENSOR, FILM SAVER DETECT — LOWER (S6L) —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-70SENSOR, FILM TRAY DETECT — UPPER (S5U) — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — -3-71SENSOR, FILM TRAY DETECT

— LOWER (S5L) — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — -3-73VACUUM PUMP (M4) — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-74PICKUP AY — UPPER — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — -3-76PICKUP

AY — LOWER — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — -3-77MOTOR, PICKUP

DRIVE — UPPER (M3U) and LOWER (M3L) — — — — — — — — — — — — — — — —

— — — — — -3-78SUCTION CUP — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— -3-79VALVE, SOLENOID — UPPER (M5U) and LOWER (M5L) — — — — — — —

— — — — — — — — — — — — — — — — — — -3-80SENSOR, PICKUP HOME —

UPPER (S1U) and LOWER (S1L) — — — — — — — — — — — — — — — — — — — —

— — -3-81SENSOR, FILM CONTACT — UPPER (S2U) and LOWER (S2L) — — — —

— — — — — — — — — — — — — — — — — -3-82SENSOR, FILM SEPARATED —

UPPER (S3U) and LOWER (S3L) — — — — — — — — — — — — — — — — — — —

-3-83IMAGING AY — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-84SENSOR, START OF PAGE (SOP, S8) — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — -3-85POWER SUPPLY — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — -3-87HARD DRIVE — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — -3-89FILM PATH MICROCONTROLLER BOARD — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-3-91DRE MOTHERBOARD — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — -3-92Preventive Maintenance — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

4-1Necessary Materials — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

4-1PM Intervals — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

4-2EM Call Checklist — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

4-2Performing the PM — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

4-3Resetting the PM Counts and Changing the Service History — — — —

— — — — — — — — — — — — — — — — — — — — — -4-10Completing the PM —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — -4-12Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 v

Diagnostics — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — 5-1Using the SERVICE SWITCH — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-1LOCAL PANEL LEDs and Buttons — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — 5-2LOCAL

PANEL Icons — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — 5-3DICOM

Printer Status Messages — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — 5-4Machine

Control System (MCS) Printer Status Messages — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — 5-5Film Supply Status

Messages — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — 5-6Job Manager Status

Messages — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — 5-8Condition Codes — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — 5-9Subsystems in the 5800 — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-9Severity Levels — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-10Condition Code: 01-000 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-11Condition Code: 01-001 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-11Condition Code: 01-002 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-12Condition Code: 01-004 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-12Condition Code: 01-005 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-13Condition Code: 01-007 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-13Condition Code: 01-008 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-14Condition Code: 01-009 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-14Condition Code: 01-010 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-15Condition Code: 04-000 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-15Condition Code: 04-100 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-16Condition Code: 04-101 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-16Condition Code: 04-110 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-17Condition Code: 04-200 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-18Condition Code: 04-201 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-18Condition Code: 04-202 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-19Condition Code: 04-300 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-19Condition Code: 04-301 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-20Condition Code: 04-302 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-20Condition Code: 05-000 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-21Condition Code: 05-001 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-21Condition Code: 05-002 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-22Condition Code: 05-003 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-22Condition Code: 05-004 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-23Condition Code: 05-005 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-23Condition Code: 06-000 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-24Condition Code: 06-001 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-24Condition Code: 06-002 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-25Condition Code: 06-101 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-26Condition Code: 06-102 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-27Condition Code: 06-103 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-27Condition Code: 06-104 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-28Condition Code: 06-105 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-28Condition Code: 06-106 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-29Condition Code: 06-200 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-29Condition Code: 06-300 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-30Condition Code: 06-400 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-30Condition Code: 06-410 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-31Condition Code: 06-411 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-32Condition Code: 06-412 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-32Condition Code: 06-420 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-33Downloaded from www.Manualslib.com manuals search engine

-

vi 2G0947 — 31JAN08

Condition Code: 06-430 — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-34Condition Code: 06-440 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-35Condition Code: 06-500 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-35Condition Code: 06-501 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-36Condition Code: 06-502 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-36Condition Code: 06-503 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-37Condition Code: 06-504 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-37Condition Code: 06-505 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-38Condition Code: 06-506 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-38Condition Code: 06-600 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-39Condition Code: 10-001 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-39Condition Code: 10-003 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-40Condition Code: 10-015 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-41Condition Code: 10-910 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-42Condition Code: 13-001 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-42Condition Code: 14-001 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-43Condition Code: 20-004 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-44Condition Code: 20-154 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-45Condition Code: 20-156 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-46Condition Code: 20-209 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-47Condition Code: 20-449 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-48Condition Code: 20-550 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-48Condition Code: 20-700 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-49Condition Code: 20-701 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-49Condition Code: 20-702 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-50Condition Code: 20-703 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-50Condition Code: 20-704 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-51Condition Code: 20-705 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-51Condition Code: 20-706 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-52Condition Code: 20-913 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-52Condition Code: 20-915 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-53Condition Code: 20-919 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-54Condition Code: 21-000 or 23-000 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-55Condition Code: 21-001 or 23-001 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-55Condition Code: 21-002 or 23-002 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-56Condition Code: 21-003 or 23-003 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-56Condition Code: 21-004 or 23-004 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-57Condition Code: 21-116 or 23-116 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-58Condition Code: 21-117 or 23-117 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-60Condition Code: 21-118 or 23-118 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-61Condition Code: 21-119 or 23-119 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-63Condition Code: 21-122 or 23-122 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-65Condition Code: 21-125 or 23-125 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-67Condition Code: 21-126 or 23-126 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-68Condition Code: 21-127 or 23-127 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-69Condition Code: 21-130 or 23-130 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-70Condition Code: 21-131 or 23-131 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-71Condition Code: 21-139 or 23-139 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-72Condition Code: 21-145 or 23-145 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-73Condition Code: 21-146 or 23-146 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-74Condition Code: 21-624 or 23-624 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-75Condition Code: 21-631 or 23-631 — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — -5-76Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 vii

Condition Code: 21-632 or 23-632 — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — 5-77Condition

Code: 25-922 — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — 5-78Condition Code:

25-931 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — 5-78Condition Code: 25-932

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — 5-79Condition Code: 26-325 — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — 5-80Condition Code: 26-326 — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — 5-81Condition Code: 26-543 — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — 5-82Condition Code: 26-544 — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-83Condition Code: 26-931 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-84Condition Code: 26-932 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-84Condition Code: 26-933 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-85Condition Code: 26-934 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-85Condition Code: 27-123 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-86Condition Code: 27-601 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-86Condition Code: 27-604 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-87Condition Code: 27-607 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-87Condition Code: 27-608 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-88Condition Code: 27-609 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-88Condition Code: 27-611 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-89Condition Code: 27-613 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-89Condition Code: 27-646 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-90Condition Code: 27-650 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-90Condition Code: 27-651 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-91Condition Code: 27-931 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-92Condition Code: 27-932 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-92Condition Code: 28-154 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-93Condition Code: 28-155 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-93Condition Code: 28-501 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-94Condition Code: 28-509 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-94Condition Code: 28-510 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-95Condition Code: 28-551 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-96Condition Code: 28-554 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-96Condition Code: 28-931 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-97Condition Code: 28-932 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-97Condition Code: 29-154 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-98Condition Code: 29-924 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-99Condition Code: 29-925 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

5-99Condition Code: 29-926 — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-100Condition Code: 29-927 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-101Condition Code: 29-931 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-102Condition Code: 29-932 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-102Condition Code: 29-945 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-103Condition Code: 29-947 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-104Condition Code: 36-931 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-104Condition Code: 36-932 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-105Condition Code: 36-935 — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-105Clearing Film Jams — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-106FIlm Jam — Error Code 2x-116 — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — -5-107Film

Jam — Error Code 2x-126 — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — -5-109Film Jam — Error

Code 26-325 — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — -5-110Film Jam — Error Codes 26-326

or 26-543 — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — -5-111Film Jam — Error Code 26-544 — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — -5-113Downloaded from www.Manualslib.com manuals search engine

-

viii 2G0947 — 31JAN08

Functions of the MICRO BOARD LEDs and Test Points — — — — — — —

— — — — — — — — — — — — — — — — — — — — — -5-114FILM PATH

MICROCONTROLLER (FPM) BOARD — — — — — — — — — — — — — — — — — — — —

— — — — — — — -5-114PROCESSOR CONTROL BOARD (PCB) — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-117Densitometer Control Board (DCB) — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — -5-118MOTORS and SENSORS — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — -5-119Using the

Logs — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — -5-120Types of Log — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-5-120APPLICATION Log — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — -5-120Illustrated Parts List — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— 6-1MAIN AY — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— 6-1FILM FEED AY — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

6-9FILM TRANSPORT AY — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — -6-15FILM

TRANSPORT ROLLER SET AY — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — -6-19PICKUP AY — Upper (10 in.)

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — -6-20PICKUP VACUUM BAR AY — Upper (10

IN.) — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — -6-22PICKUP AY — Lower (14 in.) — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— -6-23PICKUP VACUUM BAR AY — Lower (14 IN.) — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — -6-25IMAGING AY —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — -6-26PROCESSOR AY — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — -6-27PROCESSOR FRAME AY — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — -6-29PROCESSOR COVER AY — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — -6-36ELECTRONICS BRACKET AY — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-6-38FRONT COVER AY — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-6-41ACCESSORY KITS — — — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

-6-42Functional Diagrams — — — — — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

7-1Additional Service Procedures — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

8-1Making a Configuration Backup — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

8-1Restoring the Configuration — — — — — — — — — — — — — — — — — —

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

8-2Updating the THUMB DRIVE With a New Version of System Software —

— — — — — — — — — — — — — — — — — — — 8-4Upgrading the HARD DRIVE

with a New Version of System Software — «Ghosting» — — — — — — — —

— — — 8-5Upgrading the FIRMWARE in the MICROCONTROLLERS — — — — — —

— — — — — — — — — — — — — — — — — — — — — 8-7Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 1-1

Section 1: Safety InformationBefore doing the installation, read

the Safety Manual for the Kodak DryView 5800 LASER IMAGER, 2G0734.

The following information defines the safety and information icons

used in this publication.LASER WARNING:This icon is used for conditions that could cause

injury to a person, or damage to equipment or software data.CAUTION:This icon is used for conditions that could cause damage

to the equipment.Possible damage from electrostatic discharge.ESD

Electrostatic discharge (ESD) is a primary source of:

equipment failure equipment repairs

A person cannot detect an electrical charge of less than 3,500

V, but 30 V can cause damage to components in the equipment.Preventive Measures

Check for an ESD WARNING LABEL before doing any procedure with

components that are ESD sensitive. All sensitive components have

graphic LABELS that frequently include instructions. Use all label

instructions.Wear a GROUNDING STRAP when you touch components that are ESD

sensitive. Check that the CLIP remains fastened to a ground that

has a clean surface with no paint.Repair components in an ESD-protection area or use a PORTABLE

GROUNDING MAT.When moving components that are ESD sensitive from area to area,

insert and transport the components in the special material made

for the transport of these components.IMPORTANT:This icon is used for important information.

Note: This icon is used for additional information.

Downloaded from www.Manualslib.com manuals search engine

-

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-1

Section 2: Installation Instructions

Packing List

Necessary Materials

Part No. Description

2G0733 Getting Started with the Kodak DryView 5800 LASER

IMAGER2G0734 Safety Manual for the Kodak DryView 5800 LASER IMAGER

2G1249 CD — USER DOCUMENTATION for the Kodak DryView 5800 LASER

IMAGERSP2G0987 FILM TRAY AY — 10 x 8 in.

SP2G0986 FILM TRAY AY — 14 x 17 in.

SP74-0500-5710-3 NETWORK CABLE — RJ45, 2.13 m (7.0 ft.)

SP7E9349 POWER CORD — North America

SP7F3990 POWER CORD — China

SP7F6848 POWER CORD — Europe

SP2G0985 CHARCOAL FILTER

Part No. Description

—— SERVICE LAPTOP with Microsoft Windows 98 OPERATING SYSTEM

or higher, and Microsoft INTERNET EXPLORER 5.5—— SECURE LINK CLIENT SOFTWARE version 2.3 or higher

—— Service WebLink Client Software Version 3.1.0.5 or

higherTL5568 CROSSOVER CABLE

TL5574 TEMPERATURE METER and PROBE

SP7F3477 BLOCK for PROBE, KIT

—— SIDE CUTTERS

—— STRAIGHT SLOT SCREWDRIVER

—— Torx DRIVER (T20)

—— Hex WRENCH (6 mm)

—— SCISSORS

Downloaded from www.Manualslib.com manuals search engine

-

2-2 2G0947 — 31JAN08

Installation Instructions

Connecting the LAPTOP COMPUTER to the IMAGER

1. Open the TOP COVER. 2. Loosen the 2 Captive THUMB SCREWS.3.

Remove the RIGHT PANEL.4. Connect one end of the CROSSOVER CABLE to the LAPTOP COMPUTER

and the other end to the service port on the IMAGER.RIGHT PANEL

TOP COVER

2 CaptiveTHUMBSCREWS

Service port

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-3

Installation Instructions

Energizing the IMAGERRISK OF ELECTRIC SHOCK:Dangerous voltage

present.1. Check that the AC POWER CORD is connected into the back of

the IMAGER and into the wall OUTLET.CAUTION:Double Pole/Neutral Fusing.

2. Press the POWER SWITCH on the IMAGER to the ON position.

De-energizing the IMAGERCAUTION:Double Pole/Neutral Fusing.

1. Press the POWER SWITCH on the IMAGER to the OFF position.

RISK OF ELECTRIC SHOCK:Dangerous voltage present.

2. Disconnect the AC POWER CORD from the wall OUTLET.

Downloaded from www.Manualslib.com manuals search engine

-

2-4 2G0947 — 31JAN08

Installation Instructions

Logging Onto the SERVICE TOOL

IMPORTANT:

You must have the SECURE LINK CLIENT SOFTWARE, Version 2.3 or

higher and the Service WebLink Client Software, Version 3.1.0.5 or

higher installed and configured on your LAPTOP COMPUTER. Both of

these are located on the Intranet at:

http://know.us.kodak.com/audience_fe001/stage/global/en/Health-Medical/Service_Systems/index.shtmlYou will not be able to log on until 3 or 4 minutes after you

have energized the IMAGER.1. Connect the LAPTOP COMPUTER to the IMAGER (see Connecting the

LAPTOP COMPUTER to the IMAGER on page 2-2).2. Energize the LAPTOP COMPUTER.3. Select

Start>Programs>Kodak>SecureLink.4. Type your password.5.

Click [OK].6. Type the IP address of the Service Port:

192.168.000.17. Check that the Port is set to: 4438. Click

[Connect].9. Select Start>Programs>Kodak>Service

WebLink.The main menu of the SERVICE TOOL displays.

Logging Off the SERVICE TOOL1. In the right corner of the

SERVICE TOOL, click [Log Off].2. At the Kodak Service WebLink

screen, click [Log Off].3. Close the WebLink Client Software.4. At

the Secure Link screen:click [Disconnect] close the screen

5. Disconnect the LAPTOP COMPUTER from the IMAGER.6. If you are

finished with the SERVICE TOOL, install the RIGHT PANEL.Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-5

Installation Instructions

Doing the Mechanical Setup

Completing the Uncrating1. Locate and remove the box that has

the DOCUMENTATION andCABLES.2. Remove the other boxes that have the 2 FILM TRAYS and

FILTERS.3. Remove the SIDE PANELS from the CRATE.4. With SCISSORS, cut the FOIL BAG all around the BASE of the

IMAGER.5. Remove the FOIL BAG.

6. Use the Hex WRENCH to remove: 2 BOLTS 2 WASHERS

FOIL BAG

2 BOLTS and2 WASHERS

BRACKET

Downloaded from www.Manualslib.com manuals search engine

-

2-6 2G0947 — 31JAN08

Installation Instructions

7. Lift the BRACKET up and remove it.8. Do Step 6 and Step 7 for

the other BRACKETS.CAUTION:The Imager is 70 kg (155 lbs).

9. Using safe «lifting techniques», lift the IMAGER from the

shipping pallet at the locations shown above.Checking the AccessoriesCheck that the following items are

included with the CRATE:1. A box with electrical accessories: 3 POWER CORDS 1 NETWORK

CABLE2. 3 boxes with CHARCOAL FILTERS.3. A box with a 10 in. FILM

TRAY.4. A box with a 14 in. FILM TRAY.Lift point front Lift point back

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-7

Installation Instructions

Moving the IMAGER1. Move the IMAGER and accessories to the

installation area.2. Position the IMAGER to allow a space of at

least 1 m (39 in.) at the backof the IMAGER for installation of the POWER CORD and NETWORK

CABLE.Removing the SHIPPING RESTRAINTS and Packing Material

1. Open the TOP COVER.2. Loosen 2 Captive THUMB SCREWS.3. Remove

the LEFT PANEL.TOP COVER

2 CaptiveTHUMBSCREWS

LEFT PANEL

Downloaded from www.Manualslib.com manuals search engine

-

2-8 2G0947 — 31JAN08

Installation Instructions

4. Loosen 2 Captive THUMB SCREWS.5. Remove the RIGHT PANEL.6.

Close the TOP COVER.1. At the back of the IMAGER, remove: 10 SCREWS BACK PANEL

RIGHT PANEL

TOP COVER

2 CaptiveTHUMBSCREWS

BACK PANEL

10 SCREWS

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-9

Installation Instructions

2. Remove the 2 SHIPPING WASHERS from the back of the OPTICS

AY.3. Store the SHIPPING WASHERS by «pushing» the WASHERS onto

thePINS below the BAR.4. Install:

BACK PANEL 10 SCREWS LEFT PANEL

5. Open the TOP COVER.6. Pull the FRONT PANEL forward.7. Remove

the front SHIPPING WASHER and store it.OPTICS AY

SHIPPING WASHER BAR

Installed for shipping

Installed for storing

FRONT PANEL

SHIPPING WASHER

Installed for shipping

Installed for storing

TOP COVER

Downloaded from www.Manualslib.com manuals search engine

-

2-10 2G0947 — 31JAN08

Installation Instructions

8. Install the CHARCOAL FILTER.9. Close:

FRONT PANEL TOP COVER

10. Open the package of electrical accessories.

IMPORTANT:The 5800 IMAGER will automatically detect the AC power

line voltage and will automatically configure itself for the

applied voltage.11. Select a POWER CORD. Part number 7E9349 — for North American

installations Part number 7F6848 — for European installations Part

number 7F3990 — for Chinese installationsCheck that the POWER CORD

you select matches the AC power OUTLETS at the site.If the IMAGER

is located outside the areas above, you can use one of these POWER

CORDS if the PLUG matches the power OUTLETS in the building. If the

customer cannot use any of the POWER CORDS provided, the customer

must obtain a «suitable» POWER CORD locally. The customer must use

an agency-approved POWER CORD with a PLUG type «suitable» for the

customers building.CHARCOAL FILTER

TOP COVER

FRONT PANEL

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-11

Installation Instructions

One of the following single-phase, 15 A power sources, with

grounding, must be provided within 2.5 m (8 ft) of the Imager.120 V AC +6% to -10%, 60 Hz 3Hz 240 V AC 10%, 50 Hz 3Hz 250 V AC

10%, 50/60 Hz 3HzThe wire must be insulation-rated for 600 V. A dedicated line is

recommended.12. Connect: the POWER CORD, to the AC power CONNECTOR on

theIMAGER. the POWER CORD to the building AC power OUTLET. one end

of the NETWORK CABLE to the IMAGER. the other end of the NETWORK

CABLE to the customers network.AC POWERCONNECTOR

NETWORKCONNECTOR

Downloaded from www.Manualslib.com manuals search engine

-

2-12 2G0947 — 31JAN08

Installation Instructions

13. Energize the IMAGER by pressing the POWER SWITCH to the ON

position.Wait for the «startup» to complete.14. Install the 2 FILM TRAYS.

NOTE: Do not install film or the FILM SAVERS at this time.15.

Continue with Doing the Configuration.POWER SWITCH

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-13

Installation Instructions

Doing the Configuration

IMPORTANT:You must restart the IMAGER from the SERVICE TOOL in

order to permanently save configuration information.Setting the LanguageIMPORTANT:

The language is set by the customer in the WEB PORTAL.

Checking the Values for the DICOM Source Communications1.

Connect the LAPTOP COMPUTER to the IMAGER.2. Select

Configuration>DICOM SCP>Communications.3. Check: «Port Number» is 5040 «Association Limit» is 12

4. Are the values correct?

Yes No

Continue with Setting the IMAGER to be a Destination.

a. Click [Modify].b. Type the correct values.c. Click [Save].d.

Continue with Setting theIMAGER to be a Destination.

Downloaded from www.Manualslib.com manuals search engine

-

2-14 2G0947 — 31JAN08

Installation Instructions

Setting the IMAGER to be a Destination1. Select

Configuration>DICOM SCP>Destination.IMPORTANT:The AE Title, is the name by which the modalities will

recognize the IMAGER.2. Check with the customer to determine the AE Title to be

used.3. Click [Modify].4. Type the selected AE Title in the

window.5. Select the «Media» tab.Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-15

Installation Instructions

6. In the Available field, select the check box next to the

Media Type to be used.NOTE: Under normal operations, all media types should be

allowed.7. Select the «Page and Image Options» tab.NOTE: Do not disable any of the «Page Formatting» settings of

the IMAGER except if instructed by the customer.8. Click [Save].9. Continue with Setting the System Clock.

Downloaded from www.Manualslib.com manuals search engine

-

2-16 2G0947 — 31JAN08

Installation Instructions

Setting the System Clock1. Select

Configuration>System>Clock.IMPORTANT:The System Clock is set in the FACTORY. At

installation, the Time Zone has to be reset if the IMAGER is

installed in some other Time Zone. When you reset the Time Zone

value, the Time and Date should display correctly.2. Will the clock be set manually or does the customer use a

time SERVER for synchronization?3. To correct the Time Zone value:a. Click [Modify].b. If the

«Enable time synchronization» check box is selected, de-selectit.c. Select the correct Time Zone from the drop-down menu.d.

Click [Save].Manually Synchronization

Do Step 3- Step 15. a. Obtain the IP address of the SERVER from

the customer.b. Do Step 16- Step 23.

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-17

Installation Instructions

4. Is the Time value correct?

5. Is the Date correct:

6. Select System Information>User Information.7. Call the TSC

to gain a temporary Level 5 access.8. Click [Modify].9. In the

«Authorization Key:» field, type the key from the TSC.10. Click

[Save].Note: You will have Level 5 access for 24 hours.11. Return to

the Clock Configuration screen.12. Set the correct date. 13. If

daylight savings time applies in the area of installation, select

theAutomatically adjust clock for daylight savings time check box.

14. Click [Save].15. Advance to Setting the Host Name and the IP

Address.Yes No

Continue with Step 5. a. Click [Modify].b. Select a field and

use the «arrows» toincrease or decrease the time.c. Click [Save].d. Continue with

Step 5.Yes No

Advance to Step 13. Continue with Step 6.

Downloaded from www.Manualslib.com manuals search engine

-

2-18 2G0947 — 31JAN08

Installation Instructions

16. Click [Modify].17. Select the «Enable time synchronization»

check box.18. In the IP Address field, type the address of the time

SERVER to be usedfor synchronization.19. Select the synchronization period (how

often the clock is synchronized)from the drop-down menu.20. Select the correct Time Zone from

the drop-down menu.21. If daylight savings time applies in the area

of installation, select theAutomatically adjust clock for daylight savings time check box.

22. Click [Save].23. Continue with Setting the Host Name and the IP

Address.Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-19

Installation Instructions

Setting the Host Name and the IP Address1. Obtain from the

customer the Host Name, IP Address, Subnet, andGateway for the LASER IMAGER.2. Select

Configuration>System>Network.3. Click [Modify].

IMPORTANT:The Host Name is the network name for this IMAGER. It

can be a maximum of 14 characters and a minimum of one. The first

character must be a letter. Other characters can be a letter, a

number, or a -.4. Type: Host Name IP Address Subnet Mask Default Gateway

5. Click [Save].6. Continue with Setting up Service

Tracking.Downloaded from www.Manualslib.com manuals search engine

-

2-20 2G0947 — 31JAN08

Installation Instructions

Setting up Service Tracking1. Select System

Information>Identification.2. Click [Modify].

IMPORTANT:The values for Serial Number, K-Number, Windows OS ID,

and Service Code are set at the FACTORY.Model Name — set at the FACTORY, and can not be changed. Serial

Number — set at the FACTORY and can only be changed with aLevel 5 access if not correct. K-Number — can be changed if not

correct. Service Phone Number — should be filled in, and can be

changed if notcorrect. Windows OS ID — set at the FACTORY, do not change.

Service Code — set at the FACTORY, and can not be changed.3. Type

or select from the drop-down menu the correct information for

thefollowing fields: Country Code Region Hospital Name Department

Name Device LocationNote: If the K-Number or Service Phone Number are not correct,

type in the correct information before continuing with Step 4.4. Click [Save].

Downloaded from www.Manualslib.com manuals search engine

-

2G0947 — 31JAN08 2-21

Installation Instructions

5. Select Utilities>Session>Restart.6. Click

[Restart].Wait for the IMAGER to restart.7. Continue with Loading Customer

Film.Loading Customer Film1. Load customer film into the FILM