Коды ошибок, актуальные для Canon imagePROGRAF iPF670, iPF605, iPF770, iPF750, iPF710, iPF650, iPF700, iPF785, iPF610, iPF765, iPF680, iPF760, iPF510, iPF780, iPF600, iPF500, iPF685, iPF720, iPF670e, iPF671, iPF671e (для картриджей PFI-102, PFI-104, PFI-107).

Check printing results

Call for service.

Call for service.

После проверки датчика деталей в сервисном меню, замените деталь, указанную в ошибке.

Проверьте загруженные данные перед повтором печати.

Проверьте количество бумаги.

Exchange for the compatible paper to HP-GL/2.

The memory is full.

Check if there is the non-image area of the print. Verify the transmitted data before reprinting.

The memory is full.

The memory is full.

The parameter is out of range.

Verify the transmitted data before reprinting.

This command is not supported.

Delete unwanted data

Delete unneeded jobs stored in Personal Boxes.

Now printing without saving data.

Delete unneeded jobs stored in Personal Boxs.

Prepare to replace the ink.

Renew the C ink tank

Prepare to replace the ink.

Renew the M ink tank.

Prepare to replace the ink.

Renew the Y ink tank.

Prepare to replace the ink.

Renew the MBK ink tank.

Prepare to replace the ink.

Renew the BK ink tank.

Replace the ink tank.

Renew the C ink tank.

Replace the ink tank.

Renew the M ink tank.

Replace the ink tank.

Renew the Y ink tank.

Replace the ink tank.

Renew the MBK ink tank.

Replace the ink tank.

Renew the BK ink tank.

Check ink tank.

Attach the C ink tank.

Check ink tank.

Attach the M ink tank.

Check ink tank.

Attach the Y ink tank.

Check ink tank.

Attach the MBK ink tank.

Check ink tank.

Attach the BK ink tank.

Check the media size check. Change the media size.

Delete unwanted data.

Press the stop button to cancel the print job. Delete print jobs from the queue.

Delete unneeded jobs stored on the hard disk.

Press Online to clear error.

Clean the printhead. Identify the nozzles in a nozzle check pattern. Replace the printhead.

Lift the release lever and reload the paper.

Check the leading end of paper. Reload the paper.

Lift the release lever and align leading edge with orange line.

Check the sheet length. Check to see if paper has not jammed.

Lift the release lever and reload the paper.

Check the right edge of paper. Check the paper type.

Lift the release lever and reload the paper.

Check the left edge of paper.

Check the paper type.

Press Online to clear the error and readjust printhead.

Check the paper on which a pattern is printed for smears. Check the environment for interferences from outside light.

Clean the printhead.

Press Online to clear the error and readjust printhead.

Check the paper on which a pattern is printed for smears. Check the environment for interferences from outside light.

Clean the printhead.

Lift the release lever and replace paper with A4/ LTR (vertical) or larger.

Replace with A4/Letter or any larger-sized paper.

Lift the release lever and replace paper with A3/ Ledger (vertical) or larger.

Replace with A3/11″x17″ or any larger-sized paper.

Lift the release lever and replace roll with 10 in. wide or larger roll.

Replace with roll media at least 10 inches in width.

Remove paper and press Load/Eject.

Remove the paper jam and reload the paper.

Lift the release lever and reload paper.

Reload the paper.

Check supported paper sizes.

Replace with larger-sized paper.

Check supported paper sizes.

Replace with smaller-sized paper.

Press Online to clear the error.

Replace with adjustable media.

Lift the release lever.

Correct the skew in the paper and reload it.

Reload paper.

Reload the paper

Press Load/Eject and reload the paper.

Reload the paper

Lift the release lever and reload the paper.

Reload the roll media.

Press Online to clear the error.

Check to see if paper has not jammed.

Press Load/Eject and load sheets.

Load cut sheets at the paper tray port.

Press OK, remove the sheets, and load a roll.

Replace with roll media.

Press Load/Eject and load a roll.

Load roll media.

Turn printer off and install roll feed unit.

Install the roll media unit.

Lift the release lever and replace the roll.

Renew the supply of roll media.

Press Load/Eject and reload the paper.

Check the type of paper that can be fed and reload the paper.

Press Load/Eject and remove the roll.

Load cut sheets at the paper tray port.

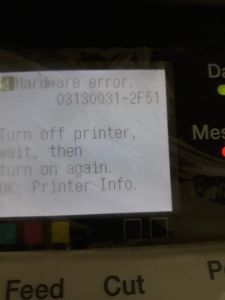

03130031-2E23

Turn off printer, wait, then turn on again.

Check the cutter unit.

03130031-2E14

Turn off printer, wait, then turn on again.

Replace the main controller PCB

03130031-2E16

Turn off printer, wait, then turn on again.

Check the mist fan.

03130031-2E17

Turn off printer, wait, then turn on again.

Check the suction fan.

03130031-2E20

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E22

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E23

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E25

Turn off printer, wait, then turn on again.

Check the carriage unit. Check the linear encoder for smears.

03130031-2E26

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts.

03130031-2E27

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts.

03130031-2E1F

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E2A

Turn off printer, wait, then turn on again.

Check the feed roller encoder and surrounding part. Check to see if paper has not jammed.

03130031-2E29

Turn off printer, wait, then turn on again.

Check the roll feed unit. Check roll media. Check to see if paper has not jammed in the printer.

03130031-2E2E

Turn off printer, wait, then turn on again.

Check the roll feed unit.

03130031-4027

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts.

03130031-2E13

Turn off printer, wait, then turn on again.

03130031-2F32

Turn off printer, wait, then turn on again.

Replace the multi sensor unit.

03130031-2F3A

Turn off printer, wait, then turn on again.

Check the ink supply unit.

03130031-2F3B

Turn off printer, wait, then turn on again.

Remove the ink tanks and then reload them. Check the main controller PCB.

03130031-2F70

Turn off printer, wait, then turn on again.

03130031-2F71

Turn off printer, wait, then turn on again.

03130031-2F72

Turn off printer, wait, then turn on again.

03130031-260E

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts. Replace the main controller PCB.

03130031-2618

Turn off printer, wait, then turn on again.

Check the power supply unit.

03130031-260F

Turn off printer, wait, then turn on again.

Turn off printer and check roll feed unit

Replace the roll feed unit.

Turn off printer, wait a while, then turn it on again.

Transmit valid ROM data.

Turn off printer, wait a while, then turn it on again.

Verify the validity of MID data before transferring it.

03130031-2F2B

Turn off printer, wait, then turn on again.

Open top cover and replace the printhead.

Replace printhead

Open top cover and replace the right printhead.

Replace printhead

Open top cover and replace the right printhead.

Replace printhead

03800500-2F40

Turn off printer, wait, then turn on again.

Проверьте блок очистки печатающей головки и окружающие детали.

Проверьте датчик управления головкой и окружающие детали.

Убедитесь, что печатающая головка установлена правильно.

Если визуально все чисто и корректно подключено, нужно пробовать:

Заменить датчик управления головкой.

Заменить главную плату контроллера.

Замените печатающую головку.

Замените каретку.

03800500-2F2F

Turn off printer, wait, then turn on again.

Замените датчик управления печатающей головкой.

Замените печатающую головку.

Identify the head management sensor unit

Replace the head management sensor unit

Replace the printhead

03800500-2F30

Turn off printer, wait, then turn on again.

Замените датчик управления печатающей головкой.

Замените печатающую головку.

Identify the head management sensor unit

Replace the head management sensor unit

Replace the printhead

Press OK and replace ink tank.

Renew the Bk ink tank

Press OK and replace ink tank.

Renew the Y ink tank

Press OK and replace ink tank.

Renew the M ink tank

Press OK and replace ink tank.

Renew the C ink tank

Press OK and replace ink tank.

Renew the MBk ink tank

Press OK and replace ink tank.

Renew the MBk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Bk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Y ink tank

Press OK and replace ink tank.

Replace with a fully replenished M ink tank

Press OK and replace ink tank.

Replace with a fully replenished C ink tank

Press OK and replace ink tank.

Replace with a fully replenished MBk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Bk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Y ink tank

Press OK and replace ink tank.

Replace with a fully replenished M ink tank

Press OK and replace ink tank.

Replace with a fully replenished C ink tank

Press OK and replace ink tank.

Replace with a fully replenished MBk ink tank

Press OK and replace ink tank.

Replace with a valid Bk ink tank

Press OK and replace ink tank.

Replace with a valid Y ink tank

Press OK and replace ink tank.

Replace with a valid M ink tank

Press OK and replace ink tank.

Replace with a valid C ink tank

Press OK and replace ink tank.

Replace with a valid MBk ink tank

Press OK and replace ink tank.

Replace with a valid MBk ink tank

Press OK and check ink tank.

Install a Bk ink tank

Press OK and check ink tank.

Install a Y ink tank

Press OK and check ink tank.

Install a M ink tank

Press OK and check ink tank.

Install a C ink tank

Press OK and check ink tank.

Install a MBk ink tank

Press OK and check ink tank.

Install a MBk ink tank

Turn off printer, wait a while, and turn it on again.

Close the top cover and turn on the printer again.

Turn off printer, wait a while, and turn it on again.

Close the ink tank cover and turn on the printer again.

Replace the maintenance cartridge.

Renew the maintenance cartridge.

Cartridge capacity.

Replace the maintenance cartridge.

Replace the maintenance cartridge.

Replace the maintenance cartridge.

Renew the maintenance cartridge.

Replace the maintenance cartridge.

Renew the maintenance cartridge.

Check roll position.

Online: Print Load/Eject:

Change Paper

Check to see if a borderless printing spacer is installed. Reload the paper.

Check paper size setting.

Online: Print

Load/Eject: Change Paper

Check the paper size. Change the paper size.

Online: Print

Stop: Stop Printing

Load/Eject: Change Paper

Renew the supply of roll media.

Lift the release lever and reload the paper.

Cut paper manually. Check the cutter.

Press Online to clear the error.

Check the multi sensor.

Check the head management sensor.

Online: Print

Stop: Stop Printing

Load/Eject: Change Paper

Exchange for the compatible paper to HP-GL/2 before reprinting.

Delete unwanted data on your computer to resume printing.

Press Stop to cancel printing.

Delete unneeded jobs stored in Personal Boxes.

Cannot save. Delete unwanted data on your computer to resume printing.

Press Stop to cancel printing.

Press OK to reformat

Press the [OK] button to start reformatting the hard disk. When formatting is finished, the printer automatically restarts.

Turn off printer, wait a while, and turn it on again.

Invalid files will be deleted.

Restart the printer. Only the corrupted files will be deleted, and the printer will restart.

Turn off printer, wait, then turn on again.

Check the head management sensor. Replace the head management sensor. Replace the printhead.

Turn off printer, wait, then turn on again.

Check the pinch roller and surrounding part. Replace the pinch roller pressure drive unit.

Install printhead.

Install the printhead.

Replace the printhead.

Check the maintenance cartridge.

Install the maintenance cartridge.

Lift the release lever and reload the paper.

Check the cutter unit and surrounding part. Replace the cutter.

Renew the supply of roll media.

Manually rewind roll all the way and press OK.

Check the pick-up unit and roll media. Check to see if paper has not jammed.

Load cut sheets at the paper tray port.

Check the media size. Change the media size.

Confirm usage cond. of the paper.

Reload the paper.

Reload the roll media.

Hardware error 03130031-2F26 is a carriage motion error. In this blog, you will learn how to troubleshoot this error. Please be sure to carefully follow the instructions, as any deviation may cause further (potentially expensive) damage.

What The Code Means

Error 2F26 displays a message on the printer that says «Power On Again Carriage Motion Error».

The longer explanation is «Carriage operation disabled. A PWM duty of 100% has lasted for 200 msec in a carriage operation. A collision has been detected in a carriage operation (with the speed predicted from the PWM output valve having a deviation of 25 ips or more from the actual speed».

Yea, that one confuses us too, and we are certified technicians.

Here are the actual causes:

- If the motor could not be run at all or has resulted in an error after moving by a slight distance.

- A mechanical load error may be suspected

- The motor or drive circuit may be at fault

- If the carriage has run more or less out of control and resulted in an error, the encoder sensor may be at fault

How To Fix It

Before trying anything, we always recommend lifting the top cover to be sure there are no paper jams, and the carriage is securely in place on the right side of the printer.

Once you have verified the above information, power cycle the printer.

If the error has cleared, you are finished with this troubleshoot.

Error Has Not Cleared

The possible causes can vary. Here are 4 scenarios:

- Heavy load to the carriage drive function — this is caused by dirt on the carriage shaft, not enough tension of the carriage belt, or a foreign object.

- Electrical trouble on the carriage drive function — caused by abnormal electrical signals or voltage, not connected properly between cable and connector, or trouble on the carriage motor.

- Trouble on the linear encoder strip — caused by dirt or a scratch on the linear encoder strip, the carriage belt does not sit properly or keep enough tension, or a crack on the flexible cable/not connected properly

- Trouble on the purge unit — can not unlock the carriage unit, capping sequence can not be done properly, or cannot detect the current condition of the purge unit.

Search Error Code Here

Easily Search For Individual Error Codes Using The Search Field Above. Contact Us If you are Having Difficulty Finding Your Code.

Check the following:

- Where the carriage unit is. There may be a defective purge unit if it is at the extreme left position.

- Check if the carriage unit moves smoothly

- Check if there is an unexpected vertical uneven line around the leading edge

- Check how the carriage unit works initializing (need the latest version of the firmware)

- Check if the linear encoder strip sits properly

- Check if there is damage to the linear encoder strip

- The carriage unit does not sit on proper position even though the locking pin is in position

If The Error Does Not Clear

A technician can verify the specific type of error in service mode. It is not recommended for «end users» to enter service mode, however, on printer models that have become unsupported by the manufacturer, it may be necessary.

We discourage anyone from making any repairs without proper training and knowledge. Ignoring our recommendation could result in severe injury or death. However, if your model is no longer supported, the following information may be helpful.

Old Printers vs. New Computers

Depending on its age, your printer may simply not be worth repairing. Older models may not have compatible drivers for new computers and operating systems.

For information on Canon’s current line of new large format printers, please see the link to the right.

2F26 isn’t my error code!

If 2F26 is not the error code displayed on your screen, please see our blog post that lists all the possible 03133310 error codes so you can learn more about your specific error.

Ron Rodgers is an Imaging Ace & Print Industry Hotshot with a passion for helping people turn print into profit! Aside from being the founder of ProPrinting Systems, he is a marketing machine, funtrepreneur (like entrepreneur but more fun), blogger, YouTuber, podcaster, musician, husband, father, sales expert, and all-around nice guy.

Related Posts

2F26 isn’t my error code!

If 2F26 is not the error code displayed on your screen, please see our blog post that lists all the possible 03133310 error codes so you can learn more about your specific error.

Ron Rodgers is an Imaging Ace & Print Industry Hotshot with a passion for helping people turn print into profit! Aside from being the founder of ProPrinting Systems, he is a marketing machine, funtrepreneur (like entrepreneur but more fun), blogger, YouTuber, podcaster, musician, husband, father, sales expert, and all-around nice guy.

Related Posts

About Ron Rodgers

Ron Rodgers is an Imaging Ace & Print Industry Hotshot with a passion for helping people turn print into profit! Aside from being the founder of ProPrinting Systems, he is a marketing machine, funtrepreneur (like entrepreneur but more fun), blogger, YouTuber, podcaster, musician, husband, father, sales expert, and all-around nice guy.